Research Article

EMERGING LESSONS ON BACKWARD AND FORWARD INTEGRATIVE TOOLS FOR ENGINEERING THE ADVANCEMENT OF MICRO INDUSTRIES IN ZIMBABWE

978

Views & Citations10

Likes & Shares

This study seeks to examine the impact of backward and forward integrative tools in engineering the advancement of micro industries' so that they potentially grow. However, these days managers are looking for strategies that reduce high input costs, increase market share and eliminate poor performance of micro industries. The emerging micro-businesses in Zimbabwe are sourcing expensive raw materials from brokers. Hence, forward, applying these approaches augment the influence of their value chain systems, which regularly results in industry growth. As such, mixing up these strategies has a relationship with various micro industries' developmental opportunities such as cost-effective measures. Thus, the study assessed the impact of backward and forward integrative tools on engineering the advancement of micro industries in Zimbabwe.

Keywords: Backward and Forward Integration, Strategic Management, Advancement. Micro industries

INTRODUCTION

A micro-industry is significant in the Zimbabwean economy due to inter-alia, employment endowment, influence on the gross domestic product, and alleviating poverty. The Confederation of Zimbabwe Industries (CZI) Survey (2011) reported that micro industries account for 60% of employment in Zimbabwe. In 2012, micro industries contributed about 70% to the GDP and employed over 8 million people, which implies that the common of the population depends on micro industries for survival. However, the enmity and competitiveness of businesses have energized the approach of seeking after various significant management techniques for the micro-industry sector to under groundbreaking changes in Zimbabwe through utilizing level and perpendicular techniques to expand into heavy industries (Köhler, 2014; Alfaro, Chor, Antras and Conconi, 2019). Accordingly, the subject of backward and forward integrative combination has consistently been at the core to inspire radical business advancement. Unfortunately, in Zimbabwe, the absence of effective strategies is restraining micro industries' turnaround efforts.

The micro industries have been experiencing expanded misfortunes that require backward and forward integration programs to increase their performance (Mugo, Minja & Njanja, 2015; Omar,2020). Thus, backward and forward system by small ventures increases their efficiency and productivity since integrative methodologies are a critical driver of economic advancement in developing countries (Kenyon, Meixell & Westfall, 2016; Shiller, 2017). However, uncoordinated strategic management depletes the potential growth of micro industries' leading to extinction (Kotler & Keller, 2014). As such, the combination of integrative methodologies is an indispensable instrument for business fortitude.

In this incident, one of the most works in strategic management is grounded for effective use of backward and forward integrative tools to engineer the development of industries (Akben-Selcuk & Yilmaz, 2011; Obermaier & Donhauser, 2012; Adeleke, Akintola, Onodugo & Akintimehin, 2019). Further, proper use of management strategies is most significant for small businesses in emerging economies. However, the lacks of integrative tools in economic activities influence unrelenting high input costs and poor customer service (Alfaro, Conconi, Fadinger & Newman, 2016). This perspective has encouraged the crucial need to carry out this study to measure the advancement of micro industries through backward and forward integration strategies because there are insufficient studies conducted in Zimbabwe. Generally, this research seeks to promote integrative programs on the advancement of micro industries since they contribute to the economy, though they have been using traditional management concepts (Omar, 2020). Therefore, the employment of backward and forward integrative strategies, in line with this study, the hypothesis is the nature of the association concerning integration strategies and the advancement of micro industries in Zimbabwe.

LITERATURE REVIEW INTEGRATION STRATEGIES

The conception of integration strategies in management is an action taken by an organization to attain superior growth (Mugo, Minja & Njanja, 2015; Steinker, Pesch & Hoberg. 2016). This approach encompasses a set of strategies in an organization to achieve competitiveness. Conversely, Kotler & Keller (2014) observed that potential strategic management tools such as backward and forward integration strategies develop businesses. According to Alfaro, Chor, Antras & Conconi (2019) agree that integrative tools are two-pronged approaches used to engineer the advancement of industries and if they are well applied; they add value to products (Omar, 2020; Rungi & Del Prete, 2018).

Forward Integration Strategy

According to (Lahiri & Narayanan,2013).(Adeleke et al., 2019). forward integration directs and controls the distribution of products or services. This strategy seeks to acquire or merge with other business entities while maintaining control over its initial business mission (Shi & Yu, 2013; Alfaro, Conconi, Fadinger & Newman, 2016). This methodology is related to the concept of the supply chain of raw materials, manufacturing, marketing and sales, and after-sales service (Mol & Kotabe. 2011; Shi & Yu, 2013; Drauz, 2014; Kotler & Keller, 2014). Generally, Köhler (2014) agrees that forward integration allows micro industries to sustain profits while minimizing losses to increase market share and gain massive control over the distribution channels. This approach is a competitive benefit that maintains high product value (Gümüş, Ray & Gurnani, 2012; Kenyon, Meixell & Westfall, 2016).

Usually, when firms internalize, they may perhaps adequately perform in the market (Obermaier, & Donhauser, 2012; Köhler, 2014). Even so, there is an enormous empirical indication that horizontal divergence across numerous activities is generally harmful to value, but it becomes significant through the use of a mixed approach. For instance, (Roberts, Wallace, & Moles, 2012). (Rungi & Del Prete,2018). show that giving a discount on a particular product, is usually done by single companies in various industries. Likewise, in an era of growing commoditization, the theoretical rationale of vertical integration is increasingly challenged by the possibility of outsourcing goods in stages of a value chain (Lahiri & Narayanan, 2013; Misund, Osmundsen & Sikveland, 2012; Alfaro, Conconi, Fadinger & Newman, 2016; Alfaro, Chor, Antras & Conconi, 2019). The use of forwarding integration by micro industries expands the control and distribution of products by moving down the supply chain. With this strategy, they gain a large number of customers.

Backward Integration Strategy

The implementation of backward integrative tools seeks to source and get raw materials for the micro-industry manufacturing plant and enable the final product to satisfy the consumer (Defever & Toubal, 2013; Drauz, 2014). The strategy makes a micro-industry cut out brokers seeking to manage competition and gain control over raw materials used in producing the end product (Kenyon, Meixell & Westfall, 2016; Lahiri, 2016; Hartman, Ogden & Hazen, 2017). Through the usage of this strategy, micro industries prevent competitors from using the same resources. Using a backward integrative approach to engineer micro industries improves their product quality to gain competitive advantage (Alfaro, Conconi, Fadinger & Newman, 2016). Micro-industry uses reverse/backward to control scarce raw materials to become more reliable and cost-effective in the supply of inputs.

Therefore it is against this background that both strategies /facts seem to be significant across industries. In line with management, all factors of production are managed using backward and forward integrative tools (Steinker, Pesch & Hoberg, 2016; Omar, 2020). Thus both backward and forward integration influence the advancement of a micro-industry.

ENGINEERING MICRO INDUSTRIES

Engineering micro industries is a strategic management concept that develops micro industries to dominate their competitors (Gümüş, Ray & Gurnani, 2012; Alfaro, Chor, Antras & Conconi, 2019). The management school (Mugo, Minja & Njanja, 2015; Adeleke, Akintola, Onodugo & Akintimehin, 2019), believes that every micro-industry needs to apply the backward and forward integrative tools to stimulate their growth. Further factors of a micro-industry production are based on their vision and mission goals to improve their competitiveness.( Kenyon, Meixell & Westfall, 2016) .It is no doubt that these strategies turn around the growth of micro industries.

Nowadays, engineering businesses using backward and forward integration are fundamental for the advancement of micro industries. In particular, the noted studies analyze the links between backward and forward integration on the advancing micro businesses. These interventions stimulate economic growth (Shiller, 2017; Mugo, Minja & Njanja, 2015). In this context, these strategies are critical in making micro-industry owners understand their role in developing their industries. In light of the above, the aim is to find the relationship between backward and forward integration and the advancement of micro industries.

THEORIES REINFORCING THE STUDY

The study is anchored on the frameworks of the growth model and cluster theory to explain events that help in exploring the research. There has been wide use of growth models to explain integrative methodologies characteristic of the advancement of micro industries. The growth model relates to the development of micro industries' trends and how they evolve from one growth stage to the other (Srinivasan, 2014). The model has existence, survival, success, maturity, and diversification stages (Yeboah, 2015). These growth stages are used as contingency variables to analyze micro industries' growth trends. However, the cluster theory promotes industrialization by promoting the sharing of resources, skills, competition, and markets in a similar geographical setup of micro industries (FAO, 2017).

CONCEPTUAL FRAMEWORK

The conceptual framework technique develops micro industries since a conceptual framework is a design showing dependent, intermediate, and micro industries variables, which all have interrelationships. The importance has been highlighted in many studies as pivotal in promoting the advancement of micro industries (Mugo, Minja & Njanja, 2015). The aim is for combining ideas from one subject area with theories to come up with a conceptual framework as indicated below (Figure1).

The conceptual framework indicated how variables are related and organized leading to the advancement of micro industries (Bakar, 2016).

MATERIALS AND METHODS

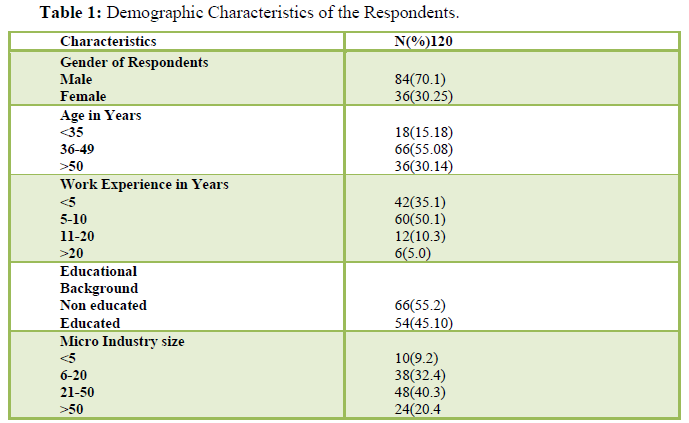

The research analyzed the approaches between backward and forward integration and micro industries advancement in Mbare's Siyaso and Magaba catchment area, Zimbabwe using questionnaires to collect data from 120 respondents. The study area has a large concentration of micro industries and the sample size was selected from the population group using a convenience sampling technique. The convenience sampling technique was good for the population because they work during the day. The collected data were analyzed using frequency distribution percentages and tables (Yin, 2013, Greener & Martelli, 2018).

FEATURES OF PARTICIPANTS

A reflected in Table 1 popular participants were male (70.1%) and (55.08%) aged between 36 and 49 years. Most (50.1%) of the respondents in the micro industries had at least ten years of work experience, while 55.2% had no formal education. Most businesses employ less than 9.2% of staff, while 40.3 % had employees in the range of 21-50 employees.

RESULTS

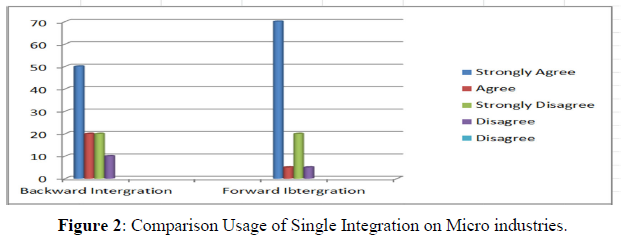

The results shown in Figure 2. indicated that forward integration was leading in developing micro industries. This is more so because micro industries are moving to control the distribution of products and services in the market (Shi & Yu, 2013; Kotler & Keller, 2014; Kenyon, Meixell & Westfall, 2016; Adeleke et a,,2019). Generally, Köhler (2014) posits that forward integration allows micro industries to sustain profits while minimizing profit losses. This approach is a competitive advantage seeking to maintain high produce and value. While on the other hand, backward integration has an average influence in engineering the advancement of micro industries (Rungi, & Del Prete, 2018).

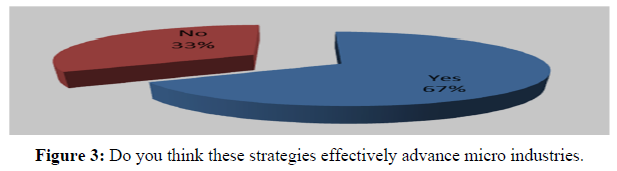

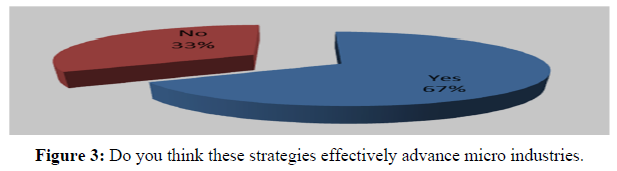

The results show in Figure 3 indicates that 67% of the respondents agree that micro industries are highly utilizing integrative methodologies in engineering the growth of this sector through cutting cost in sourcing inputs and the distribution of products to customers (Defever & Toubal,2013). However, 33% strongly disagree that these strategies are not being well applied across micro industries to influence their immediate advancement (Hartman, Ogden & Hazen, 2017).

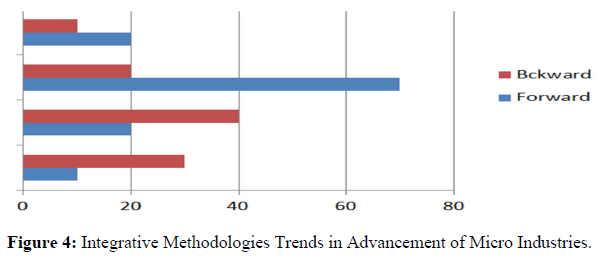

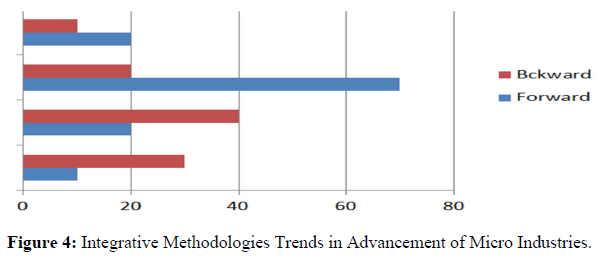

The results in Figure 4 indicate that forward integration is ahead in influencing the development of micro industries to become competitive and grow to achieve economies of scale. On the other level, backward integration equally plays a significant role in engineering the advancement of micro industries (Rungi, & Del Prete, 2018).

All the same, the hypothesis test illustrates that:

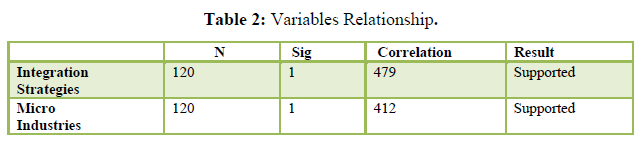

The results indicate that there is a relationship between micro industries and integration strategies. The results in Table 2 indicate that the respondents did agree that integration strategies were associated with advancing the development of micro-businesses (p>0.05). The p values of 0.479 and 0.412 are less than 0.5, indicating that the result is significant. Equally, the hypothesis showed that backward and forward integration approaches have a significant relationship with the advancement of micro industries in Zimbabwe.

DISCUSSIONS

The findings above revealed that there is a significant positive relationship between backward and forward integration methodologies and the advancement of micro industries in Zimbabwe. The resulting descriptive statistics show that most respondents agreed that backward and forward integration control channels of distribution and impact on advancing micro industries in Zimbabwe. The findings from the descriptive statistics also revealed that the majority of the respondents agreed that forward integration lowers their costs to its target markets rather than through marketing channels (Kotler & Keller, 2014; Alfaro, Conconi, Fadinger &Newman, 2016). The descriptive statistics also revealed that most respondents believe engineering their businesses using integrative tools decreases losses by cutting out intermediaries (Lahiri, 2016; Hartman, Ogden & Hazen, 2017).

Empirical research regarding forward integration concentrates on improving business performance (Akben-Selcuk & Yilmaz, 2011; Obermaier & Donhauser, 2012). The implication of backward and forward integrative methodologies has a significant relationship with the advancement of micro industries. The findings are in line with the study of (Kotler & Keller, 2014), which showed that if a micro-industry directly uses these strategies, it promotes full control of its costs, raw materials, production, and sales which are all indicators of growth-seeking to increase profits and market growth(Shi & Yu,2013; Defever& Toubal, 2013).

Furthermore, the study focused on the examination of backward and forward integration links which create a micro-industry foundation for prosperity. The research lies in the combination of backward and forward integration to investigate the basis of micro-industry advancement (Steinker, Pesch, & Hoberg, 2016). The study revealed that these integration strategies are a reference point for micro industries advancement. The application of the noted connections improves productivity, value addition and improves economic growth (Kenyon, Meixell & Westfall, 2016; Alfaro, Chor, Antras& Conconi, 2019).

CONCLUSIONS

The current study contributed to the stream of research on micro industries by focusing on the factor relationship between backward and forward integration on micro-industry advancement in Zimbabwe and as a measure to stimulate economic growth. At the same time, there is a significant relationship between micro industries and integration approaches. The comprehensive assessment of the impact of backward and forward integration on micro industries growth indicates a correlation analysis of the connection between them. Thus, the study demonstrates that integration tools eliminate poor performances and increases efficiencies of micro-industry. This study concluded that most of the Zimbabwean micro industries have not yet fully exploited the benefits of integrative methodologies. The results demonstrated a positive use of integration tools in promoting the advancement of micro industries.

The current study established that the respondents agree that integration strategies were associated with advancing the development of micro industries (p>0.05). The p values of 0.479 and 0.412 are less than 0.5, indicating that the result is significant. As such, the hypothesis of backward and forward integration approaches have a significant relationship with the advancement of micro industries. A positive change in growth perceives the effectiveness of integrative methodologies. Further, the results from this study contribute to the body of academic knowledge as the results have shown that micro industries respond favorably to integrative approaches practices. The theories in this study support the application of integrative approaches. Grounded on the key findings, it is suggested that the industry regulating authority should make compulsory integrative methodologies, using cluster systems to stimulate the development and competitiveness of micro industries. Future studies should be done at the national level to determine the effect of integrative methodologies on the growth of industries as a measure to grow the Zimbabwean economy.

ACKNOWLEDGMENT

Appreciation goes to Mbare’s Siyaso and Magaba Business Association for allowing a survey to be carried out in their business area, where there is a large concentration of micro industries.

- Adeleke, B.S. Akintola, L, Onodugo, V.A., & Akintimehin, O.O. (2019). Effect of Forward Integration Strategy on Organizational Growth Evidence from Selected Insurance and Banking Organizations in Nigeria. Academy of Strategic Management Journal 18(2), 1-14.

- Akben, E.S., & Yilmaz, A.A. (2011). The impact of mergers and acquisitions on required performance: Evidence from Turkey. Business and Economics Journal 22, 12-23.

- Alfaro, L., Conconi, P., Fadinger, H., & Newman, A. (2016). Do Price Determine Vertical Integration? Review of Economic Studies 83, 1-35.

- Alfaro, L., Chor, D., Antras, P., & Conconi, P. (2019). Internalizing global value chains: A firm-level anal-ysis. Journal of Political Economy 127(2), 508-559.

- Defever, F., & Toubal, F. (2013). Productivity, relationship-specific inputs and the sourcing modes of mul-tinationals. Journal of Economic Behavior & Organization 94, 345-357.

- Greener, S. & Martelli, J. (2018). An Introduction to Business Research Methods.

- Gümüş, M., Ray, S., & Gurnani, H. (2012). Supply-side story: Risks, guarantees, competition, and information asymmetry. Management Science 58(9), 1694-1714.

- Hartman, P.L., Ogden, J.A. & Hazen, B.T. (2017). Bring it back an examination of the insourcing decision. International Journal of Physical Distribution & Logistics Management 47(2/3), 198-221.

- Kenyon, G.N., Meixell, M.J. &Westfall.P.H. (2016). Production outsourcing and operational performance. An empirical study using secondary data. International Journal of Production Economics 171, 336-349.

- Köhler, M. (2014). Bargaining in vertical relationships and suppliers R&D profitability. Centre for European Economic Research 14, 087.

- Kotler, P., & Keller, K. (2014). Marketing management India Pearson Publishers

- Lahiri, S. (2016). Does outsourcing really improve firm performance Empirical evidence and research agenda. International Journal of Management Reviews 18(4), 464-497.

- Lahiri, N., & Narayanan, S. (2013). Vertical integration innovation and alliance portfolio size implications for firm performance. Strategic Management Journal 34(9), 1042-1064.

- Mol, M.J., & Kotabe. M. (2011). Overcoming inertia. Drivers of the outsourcing process. Long Range Planning 44(3), 160-178.

- Misund, B., Osmundsen, P., & Sikveland, M. (2012). Vertical integration and valuation of international oil companies. Journal of Business Management 7(1), 23-33.

- Mugo, M., Minja, D., & Njanja, L. (2015). The corporate growth strategies adopted by local family businesses in the manufacturing sector in Nairobi County Kenya. European Journal of Business and Innovation Research 3(1), 1-10.

- Obermaier, R., & Donhauser. A. (2012). Zero inventory and firm performance: a management paradigm revisited. International Journal of Production Research 50(16), 4543-4555.

- Omar. F.S. (2020). Impact of Vertical and Horizontal Integration Between Strategic Management Accounting and Decision-making on Reducing Financial Failures Case of Jordan. Academy of Accounting and Financial Studies Journal 24(5), 1-9.

- Roberts, A., Wallace, W., & Moles, P. (2012). Mergers and acquisitions. United Kingdom Edinburg Business School.

- Rungi, A. & Del Prete, D. (2018). The smile curve at the firm level Where value is added along supply chains. Economics Letters 164, 38-42.

- Shiller, R.J. (2017). Narrative economics. American Economic Review 107(4), 967-1004.

- Steinker, S., Pesch, M., & Hoberg, K. (2016). Inventory management under financial distress. An empirical analysis. International Journal of Production Research 54(17), 5182-5207

- Shi, M., & Yu, W. (2013). Supply chain management and financial performance literature review and future directions. International Journal of Operations & Production Management 33(10), 1283-1317.

- Yin, R.K. (2013). Case study research Design and methods. Thousand Oaks Sage publications.