1084

Views & Citations84

Likes & Shares

Micronutrient deficiencies affect over two billion people worldwide, with profound implications for lifestyle, body fitness, diseases, social factors and productivity. Fortification of main cereal or grain types food is the key tools to remove malnutrition with the cost-effective strategic plan through the optimum intake of the population such as rice kernel, consumed by peoples >440 MT/Year. Hot extrusion technology was used to produce fortified rice kernels and then blended with milled polished rice at the rate of 1:100 ratios. Fortified rice contains 0.4 mg vitamin B1, 1.0 mcg B12, 130 mcg folic acid, 150 mcg vitamin A, 4.0 mg zinc and 6.0 mg iron, respectively. Sensory analysis showed positive acceptance comparatively by 100 volunteers. The objectives of rice fortification scale-up were cost-effective methods and its consumer’s acceptance.

Keywords: Rice fortification, Fortified rice kernel, Rice blending, Micronutrient deficiencies, Acceptance

INTRODUCTION

Rice fortification is the enrichment of rice kernel with essential vitamins and minerals after post-harvesting to increase its nutritional value to remove malnutrition of vulnerable group. With more than three billion people relying on rice as their staple food, rice fortification offers a unique opportunity to substantially improve nutrition such as the health and economic status of a large number of people in many countries at a very low cost.

Globally, more than two billion people [1-3], are affected by micronutrient deficiencies, also known as hidden hunger. Micronutrient deficiencies, defined as the lack of one or more of the essential vitamins and minerals required for healthy growth, development and functioning, affect all ages and socioeconomic groups.

The consequences of hidden hunger, however, are particularly damaging for women of reproductive age and their children. Its short- and long-term consequences impact household and national level socioeconomic development and include maternal and child mortality, increased illness, mental retardation and poor cognitive and physical development. From a regulatory and public health point of view, rice fortification is similar to the fortification of wheat and maize flour, edible oil and salt – all of which have been proven effective at a large scale and are recommended by the World Health Organization (WHO) [4]. The programmatic experience and evidence base established through national-scale fortification of wheat and maize flour, oil and salt can be used to inform the introduction and expansion of rice fortification for the creation of public benefits related awareness message. In addition, WHO is developing global recommendations on rice fortification, based on a review of efficacy, effectiveness, and programmatic experience today? Today, the affordable economic technology exists to produce fortified rice kernels that look and taste the same as non-fortified rice. Due to advances in hot extrusion, cold extrusions, coating methods etc., are the popular technologies; the micronutrients are retained effectively through a multitude of preparation and cooking methods including extensive washing, and long cooking times for proper boiling as the practiced and choice ethnic meal preparation practice as any of their buying, cooking or eating habits. In Bangladesh, parboiled broken rice kernel has been considered to use considering economic price index of end-user [5,6] for hot extrusion technological aspects for fortified rice kernel preparation to scale up.

Micronutrient deficiencies

Micronutrient deficiencies are widespread, especially in developing countries and also aged group people due to decaying the functional micronutrients in the metabolic system after eating rice as their prime meal. Micronutrient deficiencies are a risk factor for many diseases like diabetes, kidney failure, obesity, renal failure, energy deficiency, insomnia, tension, Anemia, goiter, the low birth weight of the new born , pressure, depressions, etc., and also hold back growth as a common syndromes, leading in turn to reduced physical and cognitive performance and increased risks of morbidity and mortality. Micronutrient deficiencies affect all age groups but are particularly detrimental to young children and women of reproductive age. A person is affected by micronutrient deficiencies when the intake and absorption of vitamins and minerals are not balanced in their food intake, persistently insufficient to provide the body for metabolism with the quantity required for a healthy and productive life. Deficiencies of other essential micronutrients, such as zinc, folate, iron, B1 and B12, have been less well documented but are also widespread and are severely damaging cause’s neural tube defects.

The impact of fortification of rice with zinc, folic acid, vitamins B1 and B12 on micronutrient status has also been assessed. Thankachan et al. [7] studied rice fortified with iron, zinc, vitamins A, B1 and B12 and folic acid. In a study by Pinkaew et al. [8] impact on zinc status by rice fortified with iron, vitamin A and zinc was assessed. Thankachan et al. [7] found an improvement of vitamin B12 status and a decrease of homocysteine levels.

This indicated that both vitamin B12 and folic acid were well absorbed and utilized. They found no change of indicators of thiamine or zinc status. Thiamine status was already sufficient. The absence of impact of zinc fortification on serum zinc concentration, which has also been reported by other studies [9], may be due to the fact that only a small fraction of the body’s zinc pool appears in serum. This makes it insensitive to modest changes of status. The study by Pinkaew et al. [8] reported a decline of zinc deficiency in both the intervention and the control groups. The improvement of serum zinc was greater in the fortified rice group compared with the unfortified rice group.

Acceptability and biological impact of fortified rice

Different Studies have shown good acceptability of hot extruded fortified rice. In 2010, a trial assessed the acceptability of fortified rice, using hot extruded rice, in four schools in Cambodia [10]. The results showed that both kinds of rice were well accepted and even preferred when compared with traditional rice. Similar results were found in another acceptability trial conducted in Nicaragua, where both hot and cold extruded rice performed well in comparison with traditional rice [11]. Efficacy trials have been conducted to assess the impact of fortified rice on nutritional status.

In the Philippines, a 6 months trial to test the efficacy of iron-fortified rice was conducted among 218 schoolchildren. The results showed significantly higher mean hemoglobin levels and a significant reduction in the prevalence of anemia compared with the control group [12]. The Philippines [13] and India [14] among school-age children, in Brazil [15] among children 6 to 24 months and in Mexico [16] among non-pregnant and non-lactating women. All the studies showed a significant beneficial effect of fortified rice on hemoglobin levels and iron-deficiency anemia compared with control groups. These studies have shown that it is possible to use fortificants and technology for fortifying rice that results in a product that, when consumed in adequate amounts, improves micronutrient intakes and reduces micronutrient deficiencies.

To remove malnourished disease and its causes, Bangladesh government especially Food Ministry has been started scale up with local food regulatory agencies (BSTI and others) to ensure appropriate standards/guidelines to ensure fortification as per RDA. Mainly in Bangladesh, WFP and GAIN are jointly supporting Director General of Food for technical and supply chain related activities in identified malnutrition disease rich areas in Bangladesh from 2015 to until today. This Fortified rice Scale up related activities was undertaken by the Bangladesh Women and Child Affairs Ministry with the financial help of Dutch fund, Netherlands government in collaboration with WFP from 2013.

AN INNOVATIVE SOLUTION

Researcher of Nutrition and Food Engineering department under the faculty of Allied Health Sciences, Daffodil International University in collaboration with AML Food division and Massage Agro foods Ltd has advanced and commercialized the fortified rice kernel processing technology, filling an important market gap in the range of solutions for addressing micronutrient malnutrition through DG Food, Ministry of Women Welfare and Child Affairs, Dutch Agencies, WFP, PATH and GAIN. The technology packs from DSM, Netherland supplied dry premixes into rice-shaped “grains” made from per boiled broken rice flour and manufactured using hot extrusion equipment. When these fortified rice kernels are blended with milled rice (1:100), the resulting fortified rice is nearly identical to traditional rice in smell, taste and texture.

The way forward model within the food aid context, PATH has recently partnered with World Vision and the World Food Program (WFP) to test the operational feasibility and biological impact of fortified rice among schoolchildren in Burundi [17], as well as monitoring, are needed throughout the rice fortification process to ensure.

The objectives of Scaling up rice fortification of Bangladesh is a cost-effective strategy to remove micronutrient deficiencies from vulnerable the group, as a part of an integrated program to improve micronutrient health considering appropriate quality assurance and quality control, monitoring throughout the easiest technology to ensure that standards are met and that the fortified rice effectively improves the nutritional health of the consumer.

MATERIALS AND METHODS

Materials

Broken rice collected from local millers of Bangladesh and pulverized into rice powder commination into 130 mesh size (Table 1); vitamin Dry premix (DSM Nutrition products India Private Ltd., Mumbai, India) was imported as per guidelines of WFP and the premix contains Vitamin A, Folic acid, Thiamine, B12, Iron and Zinc, respectively (Table 2). Treated hot water was used for gelatinization at 70°C for 15 min in a pre-conditioner unit.

Methods

The fortification: Food fortification is the process by which one or more micronutrients are added to food during processing to increase the level of selected premixes as per RDA to restore nutrients lost during food manufacturing (e.g. by washing and milling). Food fortification has been highlighted as a very cost-effective way to address micronutrient deficiencies in the general population [18].

The technology: Extruded fortified kernels added to rice during milling at 1-1.05 kg per Metric Ton of fresh. Locally prepared broken per boiled rice flour mixed with vitamin minerals and treated were in preconditioning equipment for gelatinization temperature at 70°C for 15 min.

Extruded fortified kernels formed by combining water and a fortificant mix (vitamin minerals dry pre mix) with rice flour which was usually made from ground lower value and non-contaminated broken rice, to form a gelatinized rice powder. The gelatinized rice powder was passed through a hot extruder, producing a fortified kernel visually similar to a non-fortified rice grain. Micronutrients powder was equally distributed inside the fortified Kernel, with only a few particles left on the surface. This reduced the exposure to the environment and hence micronutrient degradation.

The amount of starch that was gelatinized in the fortified kernel influenced colour, texture and stability during soaking and cooking. This was affected by the temperature and the amount of water used during extrusion. This required binders for a subsequent boiling step to produce a cohesive product. A pre-conditioner with steam was equipped with a steam-injection device to produce fortified kernels that appear more translucent and more closely at 80-112°C using hot extruder resemble non-fortified rice. An emulsifier (MSG) was used, but no additional additives were required. In the hot extruder the pre gelatinized rice flour mixer processed at the screw pressure 77 kPa and internal temperature 108-112°C. At the end of final extrusion, the rice kernel baked mass cut into standard size by the sated cutter. After then the hot rice kernel was dehydrated into five layer vacuum drying conveying hot air exhausted drier, pass through the cooling tunnel with cold air and finally shortened using the metal detector and sieve machine. The fortified rice kernel was store at 20°C and 15-30% rdh in a control room for ageing about 24 h. During processing, similar sheen, consistency, transparency as natural rice was strongly monitored as per HACCP [19].

The resulting fortified kernels closely resemble different types of rice, with different degrees of translucency and texture. Fortified kernels made by either warm or hot extrusion were similar to non-fortified rice in their uptake of water during cooking, cooking time, and firmness. Quality assurance and quality control were needed to ensure uniform blending at the correct ratio.

RESULTS

Hot extrusion technology is the modern unit operation for fortified rice kernel processing, then blend with polished milled rice kernel @ 1:101 ratio. In this studies, low cost per boiled broken rice kernels used to differ the cost and degree of resemblance to unfortified rice.

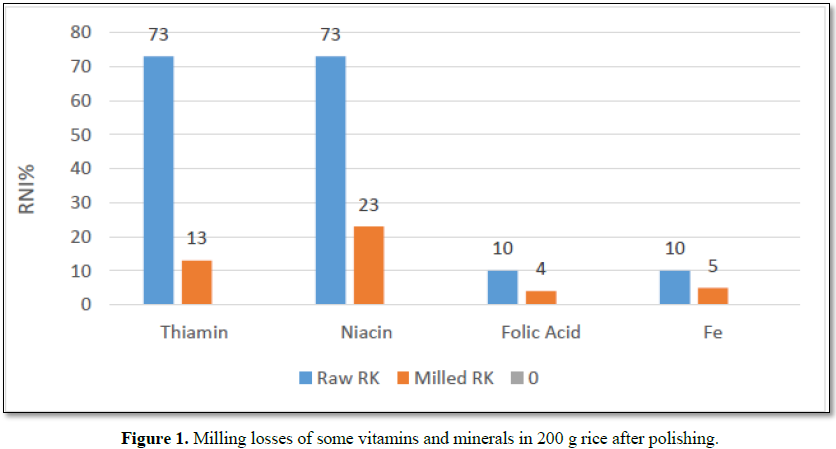

Considering the milling losses of rice kernels, the formulation was prepared as per RDA (Bangladesh) and processed using hot extrusion technology and then blended as 1:100 ratio (FRK:MRK). The finished fortified pusti rice kernels were analyzed at Wine Lab, Singapore. The result of nutrients in fortified rice kernel shown in Figure 1.

The fortified Rice Kernels sample was analyzed at Singapore, Wigine Laboratory, as technical partner of AML Ltd. and showed 0.4 mg thiamine, 150 mcg vitamin A, 130 mcg folic acid, 1.0 mcg cyanocobalamine, 4.0 mg Zn and 6.0 mg Fe per 100 g, respectively in Table 3.

After blending as per RDA of BSTI, the nutrients of 100 g fortified rice kernels were shown in Table 4.

In the chemical analysis 150 mcg vitamin A, 0.4 mg vitamin B1, 1 mcg vitamin B12, 130 mcg Folic acid, 6.0 mg Iron and 4.0 mg Zinc were investigated in fortified rice kernels, respectively.

Sensory evaluation of cooked rice

Rice consumption is deeply ingrained in culture in Bangladesh where it is the staple food.

Consuming a the particular type of rice, with specific characteristics in terms of aroma, colour and taste, often has social connotations that are rooted in traditions.

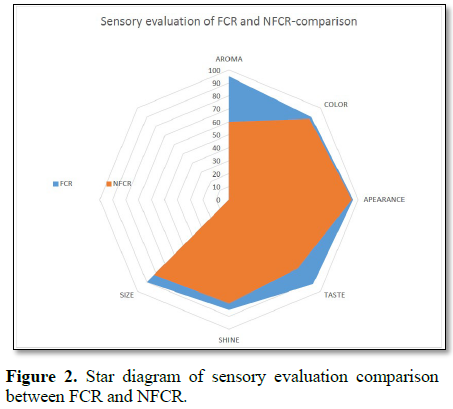

Selected volunteers were participated in sensory analysis of fortified cooked rice from AML, MAFL and NFE department. In the sensory evaluation, colour, size, taste, aroma and appearance of cooked fortified rice were supplied with prescribed questionnaires form with non-fortified cooked rice sample. The appearance, taste, shine, size and aroma of fortified cooked rice were evaluated to assess consumer acceptability. The study showed that the addition of nutrients did not affect the appearance, aroma, taste and appearance of the cooked rice.

Volunteers evaluated aroma, color, appearance, taste, shine and size of fortified cooked rice using rating 95%, 78%, 85%, 88%, 75% and 77% and 60%, 76%, 85%, 78%, 77%, 70% for non-fortified cooked rice during sensory evaluation in Figure 2.

CONCLUSION

Fortified staple food can contribute to overcoming the insufficient intake of nutrients required for a healthy and productive life in the general population. In particular, fortified Pusti Rice has the potential to be an effective tool to remove micronutrient deficiencies in the vulnerable group where rice is the major staple. So far, however, Pusti rice has only been launched on a small scale of identified poor areas through VGDP, Bangladesh Food Ministry and WFP, making Pusti rice a virtually untapped vehicle for removal of micronutrient deficiencies diseases through suitable extrusion technology, the private partners with guidelines of WFP and DSM. With a better understanding of the success factors and barriers to implementation, a more detailed area- by-area the analysis is needed to assess the appropriateness of initiating and promoting rice fortification programs in a variety of settings.

In order to effectively leverage this program, international groups involved in food assistance, market development, and agricultural value chains need to recognize the huge impact that rice fortification can have in meeting key nutritional goals around the world not in Bangladesh only.

Scale-up can only be achieved through a robust set of global implementation players, including local government, NGOs, and the private-sectors, which can fully exploit the diverse scenarios of integration across food aid channels, public-sector programs, Shopping mall, VGDP, B and traditional markets. With the converging focus on micronutrient health, improvements to domestic agricultural value chains, and the use of public-private partnerships to reach national health goals, Pusti rice is well-positioned for scale-up by the national and international development community. In appropriate contexts, organizations such as WFP may also consider using their purchasing power in addition to that of governments for promoting the growth of a market for fortified pusti rice. Furthermore, key players in the United Nations, the private sector, governments, and civil society should seek to establish coalitions institutionalizing the support for fortified rice and addressing some of the barriers to its implementation.

ACKNOWLEDGEMENT

The development of fortified rice was conducted under technical guidelines of WFP, funded by Dutch Embassy for malnutrition removing a program, Ministry of Women and Children Affairs, Bangladesh, and processing support by AML Foods Ltd. For the success of the development work by a group of food scientists from the department of NFE, Daffodil International University, Bangladesh was hardly devoted time in collaboration with Director General Food authorities and GAIN. Many thanks for all concerns of this novel research works.

1. Allen L, de Benoist B, Dary O, Hurrell R (2006) Guidelines on food fortification with micronutrients. Geneva: World Health Organization/Food and Agriculture Organization.

2. Micronutrient Initiative/Flour Fortification Initiative/Global Alliance for Improved Nutrition/World Bank/US Agency for International Development/UNICEF (2012) Investing in the future: A united call to action on vitamin and mineral deficiencies. Global Report 2009.

3. Zimmermann MB, Hurrell RF (2007) Nutritional iron deficiency. Lancet 370: 511-520.

4. World Health Organization (2009) Global prevalence of vitamin A deficiency in population at risk 1995-2005. WHO Global Database on Vitamin A Deficiency. Geneva: WHO.

5. De Benoist B, McLean E, Egli I, Cogswell M (2008) Worldwide prevalence of anemia 1993-2005: WHO Global Database on Anaemia. Geneva: World Health Organization.

6. De Benoist B, Andersson M, Egli I, Takkouche B, Allen H (2004) Iodine status worldwide: WHO Global Database on Iodine Deficiency. Geneva: World Health Organization.

7. Thankachan P, Rah JH, Thomas T, Selvam S, Amalrajan V, et al. (2012) Multiple micronutrient fortified rice affects physical performance and plasma vitamin B12 and homocysteine concentrations of Indian school children. J Nutr 142: 846-852.

8. Pinkaew S, Winichagoon P, Hurrell RF, Wegmuller R (2013) Extruded rice grains fortified with zinc, iron and vitamin A increase zinc status of Thai school children when incorporated into a school lunch program. J Nutr 143: 362-368.

9. Hess SY, Brown KH (2009) Impact of zinc fortification on zinc nutrition. Food Nutr Bull 30: S79-107.

10. Burja K, Kong K, Berger J, de Margerie JP, Dijkhuizen MA, Wieringa FT (2010) Acceptability of rice fortified with micronutrients in a WFP school meal program in Cambodia. Public Health Nutr 13: 53-54.

11. Reyes CM, Alvarado M (2010) Technology assessment of rice fortification in Nicaragua. New York: UNICEF.

12. Florentino R (2001) Iron fortification studies in the Philippines. Proceedings of the Annual Meeting of the International Nutritional Anemia Consultative Group (INACG).New York: Nutrition Foundation.

13. Angeles-Agdeppa A, Capanzana MV, Barba CVC, Florentino R, Takanashi K (2008) Efficacy of iron-fortified rice in reducing anemia among school children in the Philippines. Int J Vitam Nutr Res 78: 74-86.

14. Moretti D, Zimmermann MB, Muthayya S, Thankachan P, Lee C, et al. (2006) Extruded rice fortified with micronized ground ferric pyrophosphate reduces iron deficiency in Indian school children: A double blind randomized controlled trial. Am J Clin Nutr 84: 822-829.

15. Beinner MA, Velasquez-Melendez G, Pessoa MC, Greiner T (2010) Iron-fortified rice is as efficacious as supplemental iron drops in infants and young children. J Nutr 40: 49-53.

16. Hotz C, Porcayo M, Onofre G, Garcia-Guerra A, Elliot T, et al. (2008) Efficacy of iron-fortified ultra-rice in improving the iron status of women in Mexico. Food Nutr Bull 29: 140-149.

17. PATH (2012) Rice fortification - Ready to be scaled up by the global development community. 2201, Westlake Avenue, Suite 200 Seattle, WA 98109.

18. Bezanson K, Isenman P (2010) Scaling up nutrition - A framework for action. Food Nutr Bull 31: 178-186.

19. DSM SOP (2013) DSM nutritional products. 30 Pasir Panjang Road, Maple tree Business City, #13-31 Singapore 117440.

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Astronomy and Space Research

- Journal of Womens Health and Safety Research (ISSN:2577-1388)

- Journal of Veterinary and Marine Sciences (ISSN: 2689-7830)

- Journal of Genetics and Cell Biology (ISSN:2639-3360)

- Journal of Microbiology and Microbial Infections (ISSN: 2689-7660)

- Advances in Nanomedicine and Nanotechnology Research (ISSN: 2688-5476)

- Journal of Genomic Medicine and Pharmacogenomics (ISSN:2474-4670)