Research Article

An Innovative Approach to Managing Closed Landfills in Industrial Parks: Toward Environmentally Sustainable Industrial Development

6396

Views & Citations5396

Likes & Shares

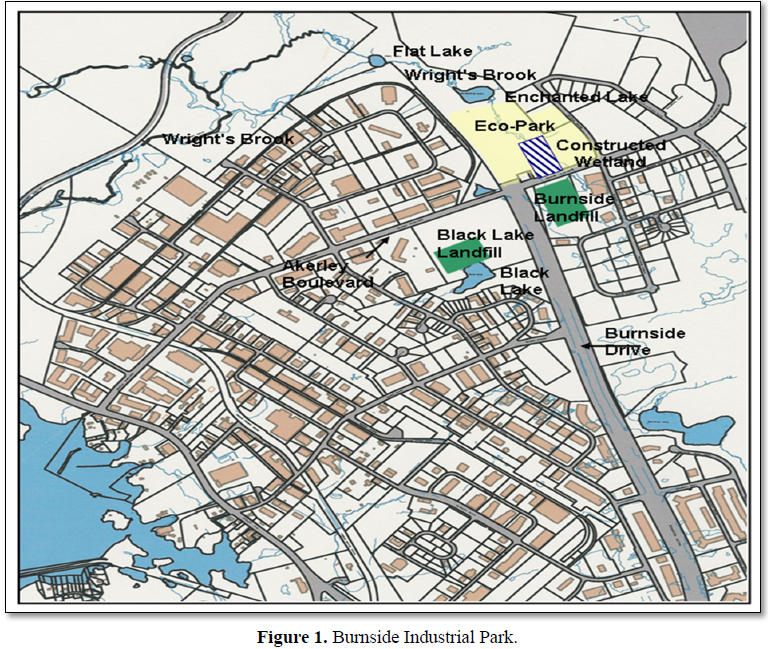

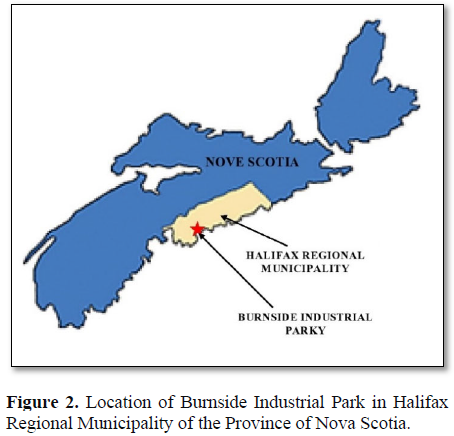

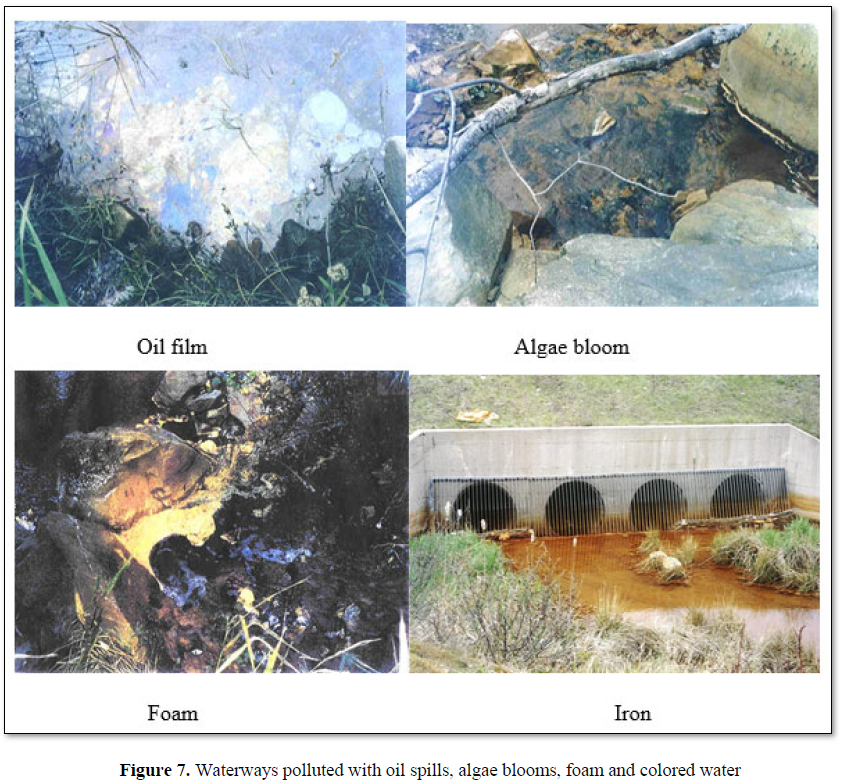

Industrial parks are becoming noticeable features of the global landscape. Due to their improperly planned construction and the nature of the industries located in them, some parks are blights in the landscape with attendant health and environmental impacts. The Burnside Industrial Park in Halifax Regional Municipality, Nova Scotia, Canada is an example of these. The 3,500-acre park is located at the north end of the city of Dartmouth and houses over 1500 medium and large size businesses employing over 25 000 people. The rapid development of the park and the continued increase in the established industries has led to drastic increase in waste production. One component of the solid waste management of the past was an open dump site, which was the main method of disposal for over 20 years. It was used with no regard for the environment, pollution control or aesthetics. The waste deposited included municipal, industrial, agricultural and demolition wastes as well as old tires and automobiles. The site served as a burning ground, as a solution to volume reduction. The leachates from the landfill and the runoff from past and new developments in the park are finding their way into Wright's Brook, Enchanted Lake, Flat Lake and Halifax Harbor. These waterways are also polluted with old tires, oil spills, algae blooms, foams and various chemicals including aluminum, arsenic, cadmium, calcium, chloride, chromium, copper, iron, lead, manganese, magnesium, potassium, sodium, strontium, zinc, ammonium sulphate, benzo(a)pyrene and phenantherene. In this project, we developed a 21 acres low land into environmental park (Eco-Park) that included a surface flow engineered wetland, an environmental sculpture with a solar powered model scale water purification system, trails, rock gardens and bridges. The Eco-Park was also planned to have educational signage to provide information to visitors. The project's goals were to protect natural waterways, protect and enhance wildlife habitats, foster environmental awareness and conservation of biodiversity through technical, cultural, and artistic expressions. The site is intended to be used as a tourist attraction and recreational facility and to serve as an outdoor educational facility for elementary and secondary schools and university students.

Keywords: Industrial parks, Landfills, Waterways, Environmental Impact, Management, Eco Park, Wetland, Rock Garden, Environmental Education. Recreation

INTRODUCTION

Industrial Park

Industrial parks are becoming more noticeable features of the Canadian and global landscape. There are more than 1,000 industrial parks in Canada and more than 15,000 worldwide. An industrial park is an area zoned and planned for the purpose of industrial development [1,2]. It can be thought of as a more "heavyweight" version of a business park or office park, which has offices and light industry, rather than heavy industry. It may contain water tower, ports, warehouses, distribution centers, offices, hotels, factories and companies that provide transportation and storage facilities such as chemical plants and beverage manufacturers. Industrial parks are usually located on the edges of, or outside, the main residential area of a city and are normally provided with good transportation access. Industrial parks are important to commerce and the idea of setting land aside through this type of zoning has several purposes [3-6]:

- To concentrate dedicated infrastructure in a delimited area in order to reduce the per-business cost of that infrastructure (includes roadways, railroad sidings, ports, high-power electric supplies, high-end communications cables, large-volume water supplies, and high-volume gas lines).

- To attract new business by providing an integrated infrastructure in one location.

- To bring companies together that provide services and features that are complementary to each other.

- To provide access for commodities and finished products to be brought to major industrial hubs for distribution.

- To set apart industrial uses from urban areas in order to reduce the environmental and social impact of the industrial uses.

- To provide for localized environmental controls that are specific to the needs of an industrial area.

Several authors [2,4-6] reported the benefits of industrial parks to small industries and occupants of the park. These can be summarized as follows:

- Economy of scale: Units located in an industrial park can adopt centralized buying and selling as the requirement of all the members for raw materials and components can be pooled together and bulk purchases made which would be eligible for quantity discounts resulting in lower costs. Also, the products of members can be pooled together and sold which would reduce selling costs.

- Economy of agglomeration: Agglomeration achieves the benefit of reduced production costs because of concentration of industries which include: (a) availability of skilled labor, (b) presence of repair, maintenance and service facilities, (c) availability of components and (d) presence of financial institutions, all within the industrial park.

- Inter-relatedness: The finished product of one unit can be the raw material for another unit. Having the units located close to each other would result in savings in transportation costs for the purchaser and reduced selling cost for the seller.

- Low investment: Since the government provides land for setting up industrial parks at affordable costs, the initial investment is low which allows small industrialists to acquire assets on purchase or lease.

- Availability of infrastructure: Electricity, water, roads, telecom, insurance companies and other facilities are readily available in industrial parks and as such entrepreneurs need not to spend time and money to get electricity, water and telephone connection and, therefore production can commence immediately.

- Availability of support facilities: Apart from the basic infrastructure, banks, post offices, restaurants, coffee shops and hotels are available in industrial parks.

- Mutual co-operation: The units in an industrial estate can cooperate among themselves by undertaking joint research to explore new markets, new sources of raw materials, better processes and best practices relating to total quality management (TQM), total productive maintenance (TPM), international standard organization (ISO) standards which will improve quality and reduce cost.

- Focus on growth: Since the initial investment is low and all the basic and supporting infrastructural facilities are readily available, entrepreneurs can focus their full attention on the business and concentrate on its growth.

- Increased employment opportunities: Industrial parks create more employment opportunities and increase the mobility of labor. Since many of the units are labor intensive, there are opportunities for both skilled and unskilled workers.

- Development of backward areas: With the development of industrial parks, a host of background facilities such as banks, post offices, insurance companies, housing, schools, health care facilities come up which balance regional development and provide employment to the local youth.

On the downside, industrial parks often create environmental worries, due to increased pollution and the potential for the grounds and surrounding area to be damaged by contaminants. The improperly planned construction of industrial parks and the nature of the industries located in them can make some parks blights in the landscape with serious health and environmental impacts [7,8]. In addition, industrial parks can combine a mix of production, transportation and storage facilities in the same area including chemical plants, plastics manufacturers, food and beverage processors, cold-storage facility, warehouses and engine parts companies and steel manufacturers all of which can be aa major source of pollution if not managed properly. The concentration of heavy industry in industrial parks can also raise environmental concerns as the pollution can be magnified by the close proximity of manufacturing facilities, machinery and heavy transportation to residential areas [9,10]. The grounds where these facilities operate can build up contaminants that make the surrounding area undesirable for residential or retail use. The constant movement of cargo on semitrailers can lead to traffic congestion in the area if the highway engineering cannot accommodate the heavy flow. It is not uncommon for lower-income housing to be located adjacent to industrial parks. The potential for excess noise, traffic and pollution can drive down prices in the surrounding residential market [11-18].

Burnside Industrial Park

The Burnside Industrial Park (Figure 1) located in the north part of the city of Dartmouth. Halifax Regional Municipality, Nova Scotia, Canada (Figure 2). The park size is about 3400 acres and has experienced rapid growth since the early 1970s. It is the largest industrial park in Atlantic Canada. Currently the park has over 2000 businesses and over 35000 employees which make it the largest industrial park north of Boston and east of Montreal. The Burnside Industrial Park is located adjacent to five 100-series highways (Highways 101, 102, 107, 111 and 118) as well as highways 7 and 33 which provide quick access to and from the park. Additionally, businesses in the park are located within 10 km from Downtown Halifax, 21 km from the Halifax International Airport, 5 km from Port of Halifax. Burnside Industrial Park has superb public transit links and is extensively serviced by C.N.R. mainline, siding, and common user facilities. It is home to the largest concentration of truck transportation in Atlantic Canada. Cranes and other heavy lifting equipment available at the park are used to transfer the cargo to trucks and railroad cars. The cargo can also be stored at warehouses located within the industrial park. Manufacturers located the park have port access which can quickly procure the materials they need to create their products. Due to the size and nature of the park, there are several hotels oriented towards business travelers located within its boundaries, including Ramada, Day's Inn, Best Western and a Comfort Inn.

However, when developing Burnside industrial park, some natural wetlands were compromised to make the land suitable for buildings leaving only a few wetlands including the headwaters of Wright's Brook. Also. the improperly planned construction of the park and the nature of the industries located in it resulted in serious health and environmental problems. In addition, the solid waste disposal system of the past in the Park consisted of two open dump sites that received municipal, agricultural, and industrial wastes which added to environmental problems. However, through work undertaken by Dalhousie University [2,4,3-14] with the support of the Halifax Regional Municipality, Environment Canada and Private Organizations, it has been demonstrated that this does not

have to be the case. Industrial parks can and should be designed and operated in a manner which is more compatible with natural and cultural amenities of an area.

EXPERIMENTAL WORK

Landfills

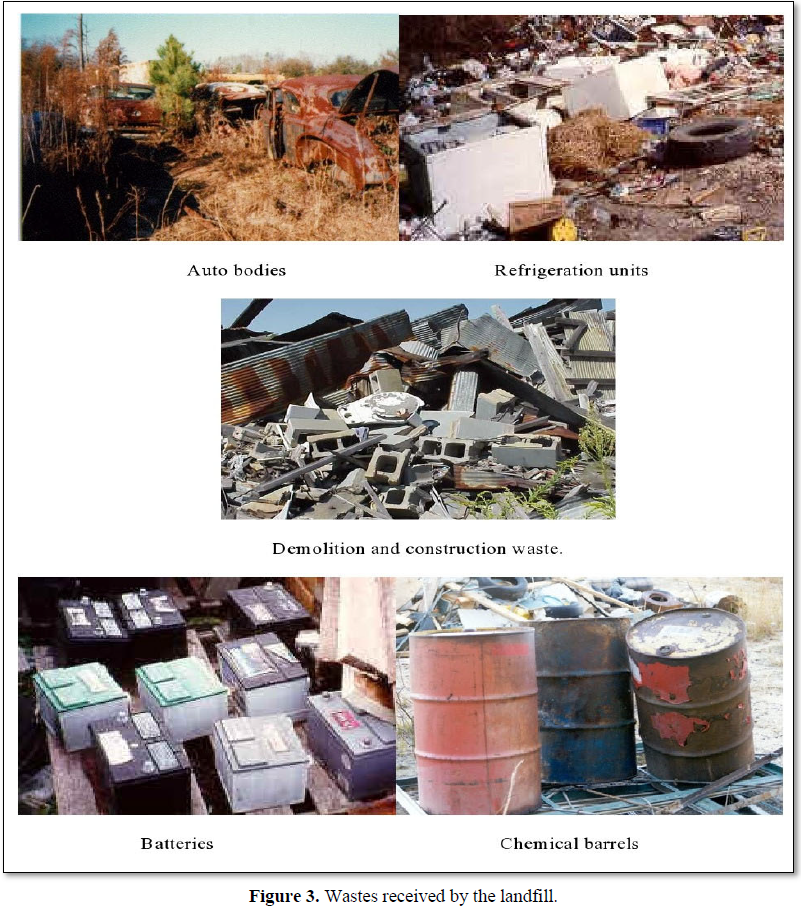

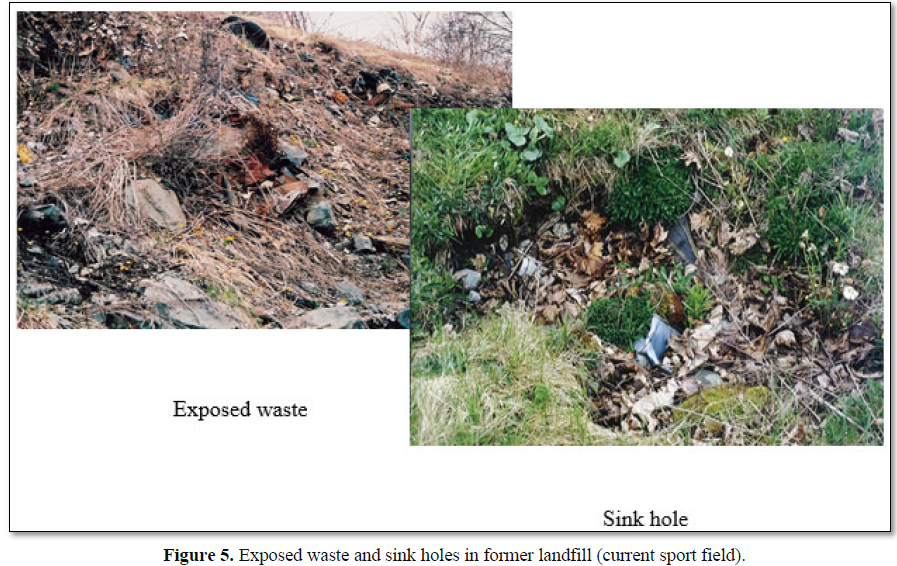

The rapid development of Burnside Industrial Park and the increase in the number of established industries has led to a drastic increase in waste production. One component of the solid waste disposal system of the past in the Park consisted of two open dump sites. These sites had accepted municipal, agricultural, and industrial wastes, old tires and cars, batteries and demolition wastes (Figure 3). The wastes were burned to reduce volume.

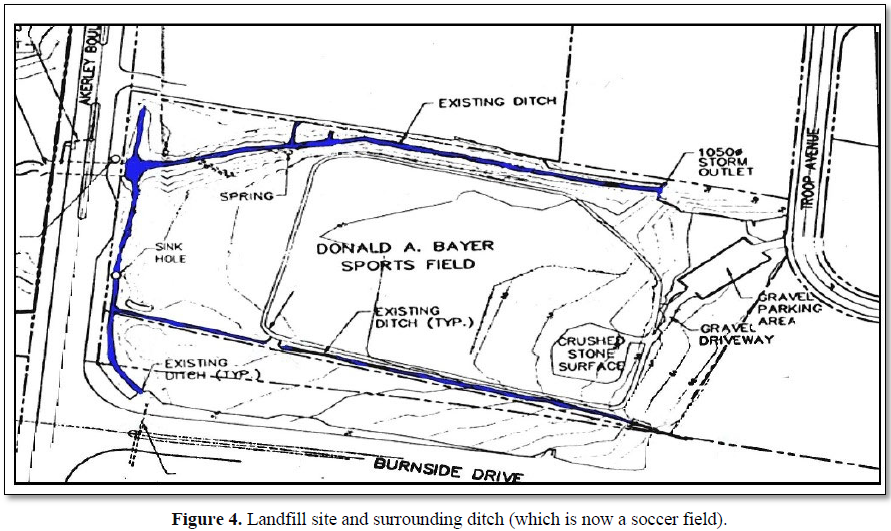

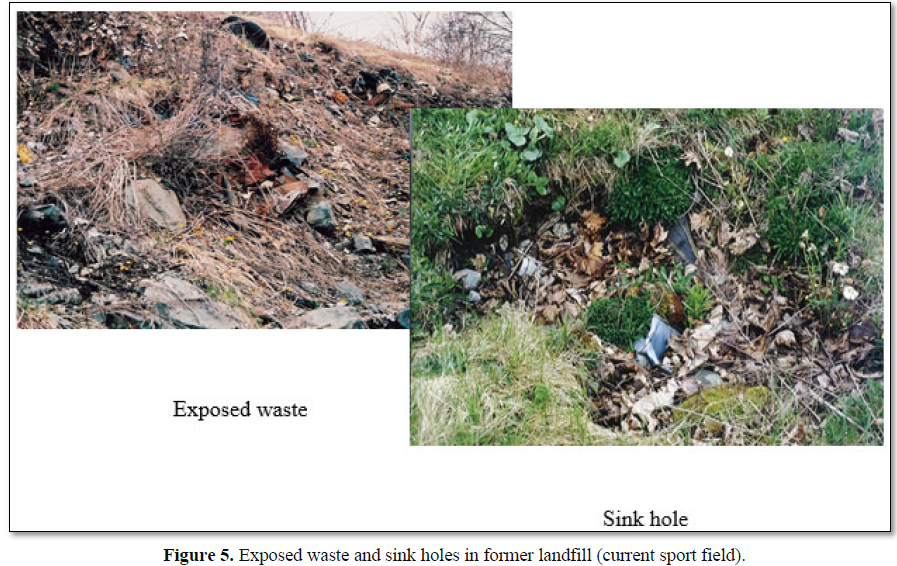

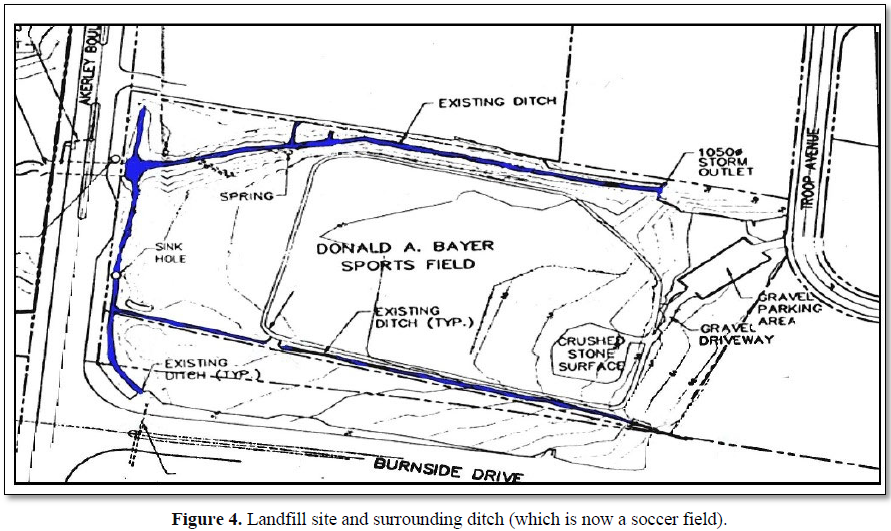

The first refuse disposal site (13.2 acres) was created by the Dartmouth Municipality in 1968 just north of Black Lake. It was closed in 1974, with very inconsistent covering. The disposal materials raised the height of the open clay soil to about 25 feet above the lake level. Scouring on the hillside above the lake, from which an extensive amount of fill had been taken, exposed soil in a harmful position in relation to the lake and surrounding areas. The Dartmouth Municipality used another open waste disposal site (13.4-acres), located at the corner of Akerley Boulevard and Burnside Drive, as a temporary landfill in 1976. Upon closure in 1977, the waste was covered with 60 cm of soil and later became the Don Bayer's Sports Field (Figure 4). The covering of the landfill involved several operations including rat and fire control, grading the dump surface, compacting and covering the surface with two feet of soil. Some of the remaining material and fill can still be seen in several sink holes (Figure 5).

Site Investigation and Runoff Estimation

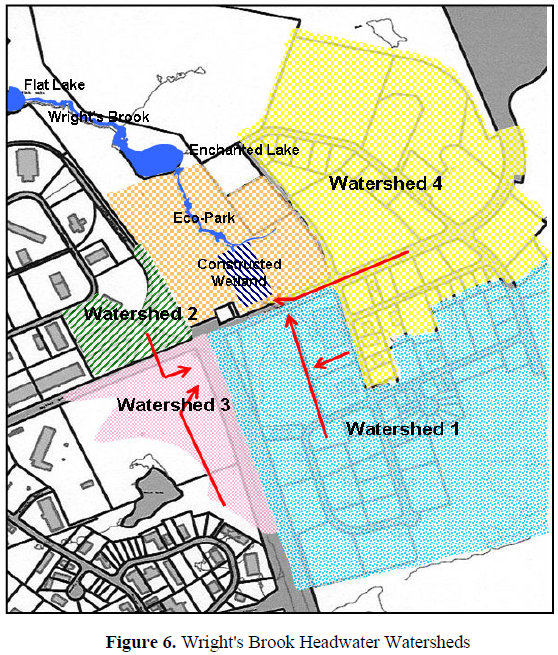

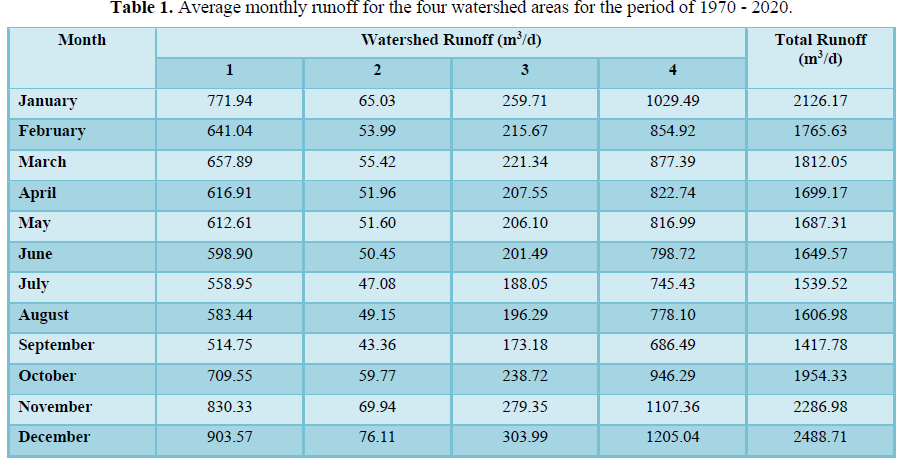

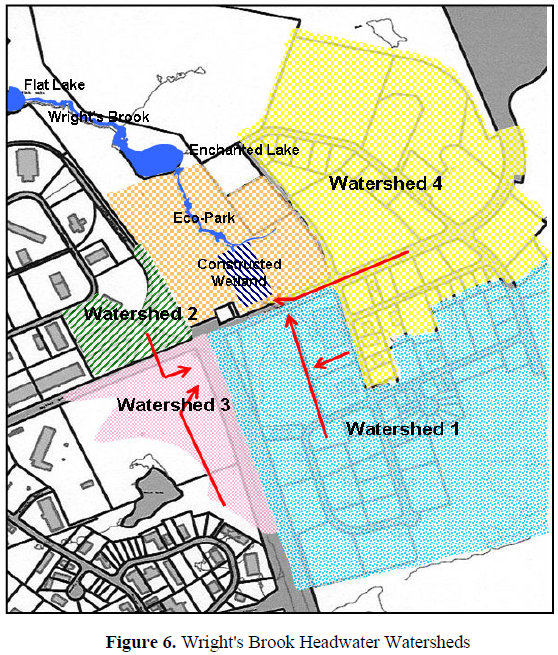

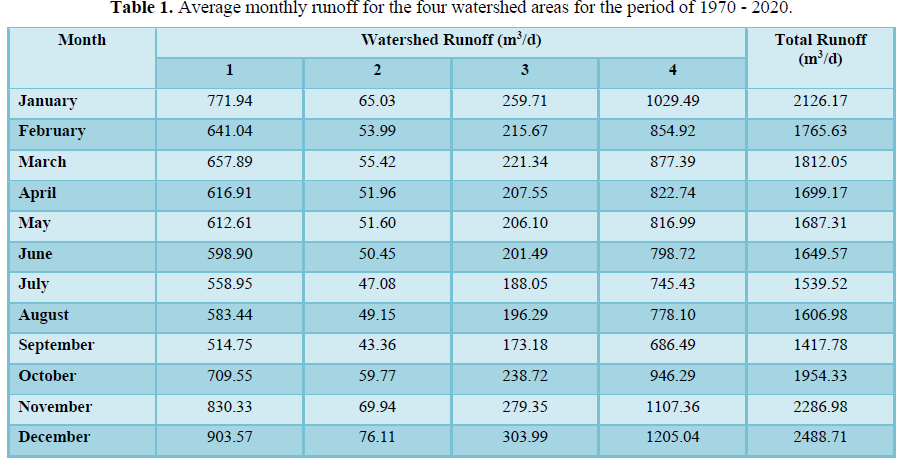

In the Spring of 2003, site investigations lead to the discovery of four watershed areas which directly drained into Wright's Brook (Figure 6). Watershed 1 is approximately 68.7 ha and it supports several commercial buildings and adjoining parking areas as well as ungraded lots undergoing development along the southern and eastern boundaries of the site. Drains collecting stormwater from areas surrounding Frazee Avenue, Troop Avenue and Williams Avenue connect at Frazee Avenue and drain into the stormwater ditch framing the eastern boundary of the Don Bayer Sports Field, which drains into the Wright’s Brook through a culvert system. Watershed 2 is located on the northern side of Akerley Boulevard and is approximately 3.4 ha. It receives water from the parking lots of two commercial buildings and drains initially, through a culvert beneath Akerley Boulevard, into a dense cattail-dominated wetland on the southwestern corner of Akerley Boulevard and Burnside Drive which is often occupied by waterfowl, then into the northern storm water ditch of the Don Bayer Sports Field and ultimately into Wright's Brook. Watershed 3 encompasses the southwestern corner of Akerley Boulevard and Burnside Drive and is approximately 13.2 ha. It includes the decommissioned Black Lake Landfill, which currently serves as a disposal site and storage area for the City of Dartmouth. The watershed is steeply sloped to the northeast and drains first into a dense cattail dominated natural wetland system, then through a culvert beneath Burnside Drive into the northern storm water ditch of the Don Bayer Sports Field, and ultimately into Wright's Brook. Watershed 4 encompasses areas on both the north and south sides of Akerley Boulevard and is approximately 51.6 ha. It supports commercially developed areas as well as undeveloped wooded areas, especially along the eastern boundaries of Gloria McCulskey and John Savage Avenues. It drains directly into the mouth of Wright Brook via a culvert beneath Akerley Boulevard. The total monthly runoff for each watershed area is presented in Table 1. The information presented was obtained from the Shearwater A Weather Station in Dartmouth, Nova Scotia [19].

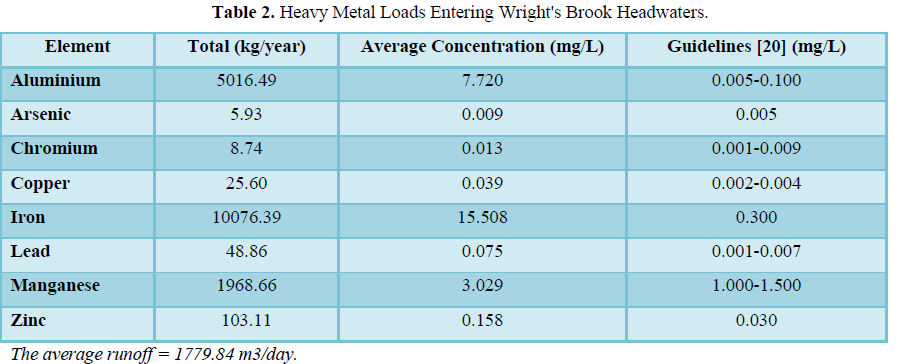

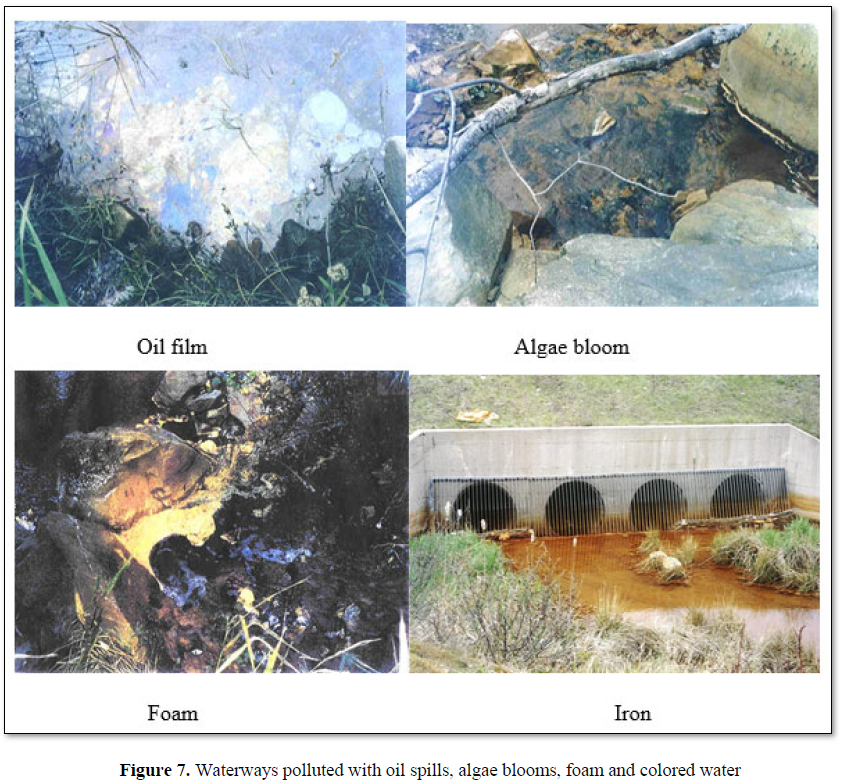

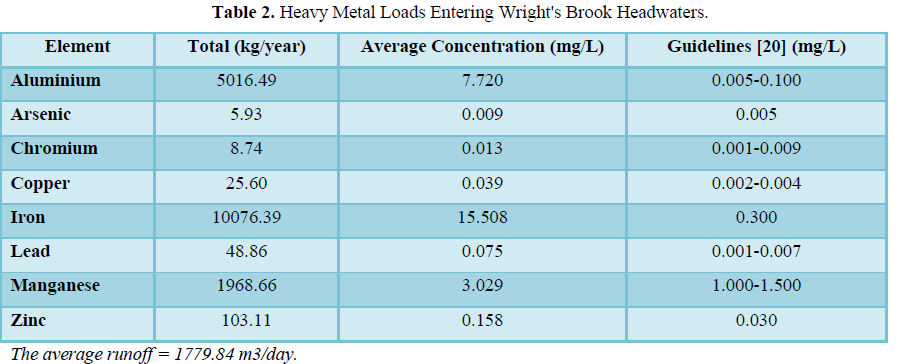

Water Sampling and Analysis

The leachate from the two landfills and the runoff from the watersheds are finding their way to Wright’s Brook, Enchanted Lake, Flat Lake, and Halifax Harbor. These waterways are polluted with old tires, oil spills, algae blooms and foams of various chemicals (Figure 7) that are causing an array of health and environmental problems. The release of toxic chemicals into the environment usually results in exposure to plants and animals. The significance of some chemicals (heavy metals, nitrogenous compounds, hydrocarbons, etc.) is their capacity to cause adverse effects at minute concentrations. These organisms may experience behavioral changes, reduction in population and diversity of species. As the concentration increases (bioaccumulation), the toxic effects (which occur shortly after exposure) may lead to death. Chemical analyses performed on the water samples taken from the brook (Table 2) indicated the need for remediation.

DESIGN OF ECO-PARK

Burnside Industrial Park was the primary case study used in the preparation of a Technical Guide to Environmental Management of Industrial Estates published by the United Nations Environment Programme [18]. The Park is in the early stages of the transformation into a model of environmental management. It has received considerable international attention and continues to receive visitors from the United States, Europe and Asia. This project would assist in ensuring that this Park develops into a model of sustainable industrial development, thereby providing a lasting legacy for Canada A and the world into the next Millennium.

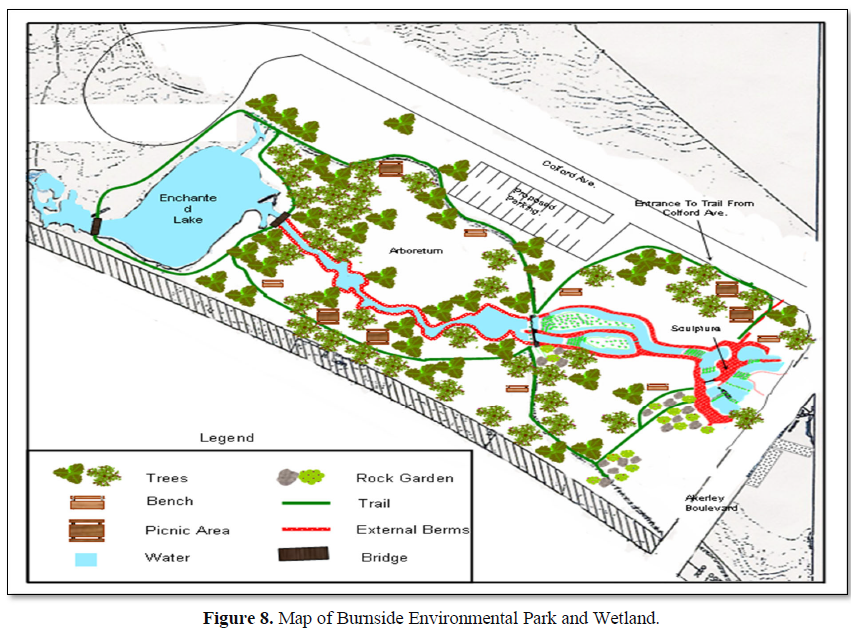

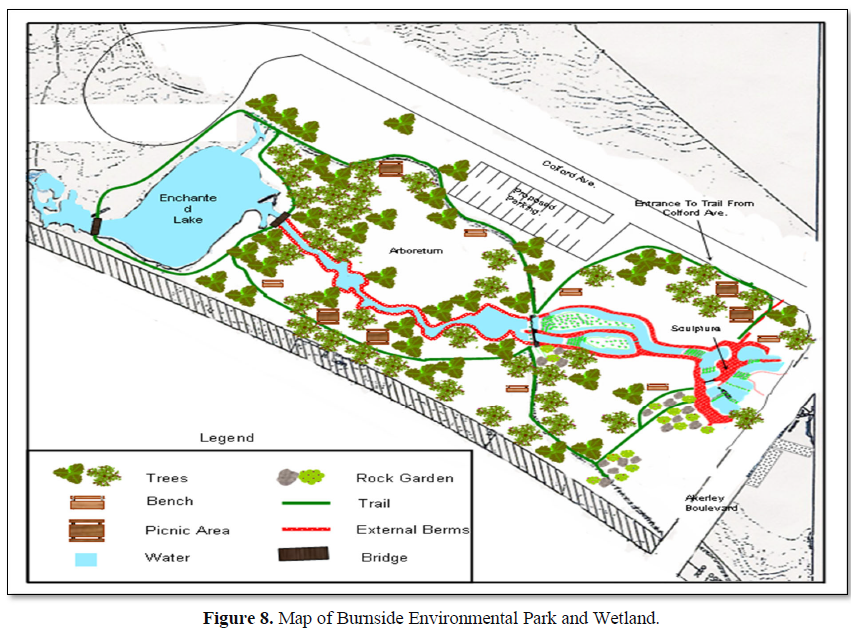

The project involved the development of the 24-acre parcel of land (designated as wetlands), located between Akerley Boulevard (West) Colford Avenue (North) Nova Scotia Correctional Facility (East) and the proposed Burnside Drive extension (South), into an Environmental Park (Eco-Park). The Eco-Park included an engineered wetland, trails, picnic areas, educational signage, environmental sculpture, arboretum, rock gardens and bridges (Figure 8).

The aim of the overall project was to protect natural waterways and foster environmental awareness through technical, cultural and artistic expressions. The specific objectives were:

- To enhance the treatment of leachate from the old landfill and the runoff from past and new industrial developments through the use of a constructed wetland to protect and restore a beautiful natural waterway (Wright’s Brook, Enchanted Lake and Flat Lake) and to maintain it as an efficient and sustainable ecosystem.

- To increase the public awareness of the importance of natural and constructed wetlands as efficient ecosystems.

- To increase the awareness of the business community in the industrial park of the importance of ecological functions in protecting their health and their environment.

- To increase the public awareness of the potential consequences of toxic substances and inadequate waste disposal sites.

- To show that HRM can lead the world by implementing models of sustainable industrial development that incorporate ecological, recreational and cultural dimensions in industrial parks.

- To provide recreational facilities for the inhabitants of Burnside Industrial Park (over 35, 000) and District 9 (over 2,0000).

- To provide an outdoor educational facility for elementary, high school and university students and the general public.

Construction and Testing of the Wetland (Treatment aspects)

Natural wetlands have been disappearing at a relatively fast rate, especially in urban areas. This is due in part to a view that these areas are "swamps" or wastelands. In fact, a wetland is a complex ecological system (wildlife habitat) of microorganisms, plants, amphibians, fish, mammals and birds that have evolved to such a high level of efficiency that very few of the nutrients, solids and sediments entering the wetland ever leave. Wetlands are the ecological space that wildlife utilizes for shelter, food, water, living space and other life history requirements. They provide important ecological functions such as providing water recharge areas, filtering of contaminants in water and as compensating mechanisms during flood conditions. No other ecological system except for the rainforest is as effective as the wetland. Artificial or engineered wetlands have been established in several places in Canada, but our research shows that none of these wetlands has been incorporated into an industrial park.

Work of the engineered wetland began at the mouth of Wright’s Brook, where the leachates from the two landfills and the runoff from industrial commercial properties (137 ha watersheds) enter. The engineered wetland was designed as multiple cell compartments consisting of alternating deep and shallow vegetative cells in series. This design allows high efficiencies of the physical, chemical and biological processes, allows the cells to act as solids traps and provides the redistribution of flow over the entire wetland. The natural gravitational flow facilitated by the site topography negated the need for any mechanical infrastructure such as pumps that would require regular maintenance by a professional, and electricity. The plant species found on the island that are adapted to grow in saturated conditions and act as a host for microbial populations were selected so that the most productive ecological system is achieved. The natural assimilative capacity of the microbial factors (bacteria and fungi) that attach to the plants provides efficient and reliable removal of organic compounds and nitrogen. Metals and phosphorus are absorbed by the plants. Birds and mammals are provided a natural habitat to exist. The engineered wetland, function as the kidneys of Wright’s Brook, trapping and transforming sediments and nutrients and purifying the wastewater naturally. Several physical, chemical and biological treatment processes are taking place in the wetland including sorption, adsorption, sedimentation, chemical reactions, biological conversions, decay, and volatilization.

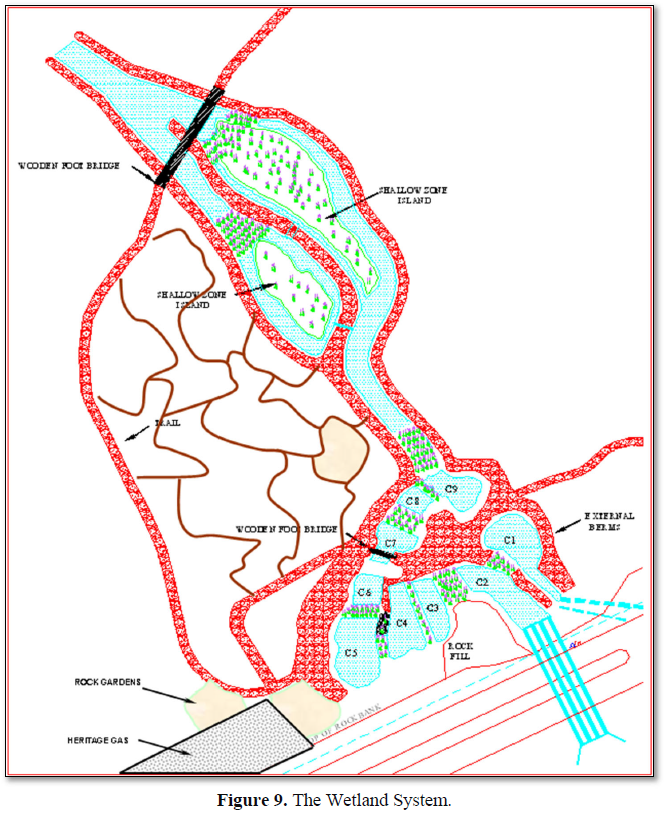

The wetland treatment system (Figure 9) consists of 9 cells (deep open waters) separated by 9 internal berms (vegetated shallow areas) and surrounded by a system of external berms, a main ditch and 2 islands (vegetated cells) separated by three internal berms (vegetated areas) and surrounded by four ditches. The two islands are naturally vegetated. While the other 9 cells were planted.

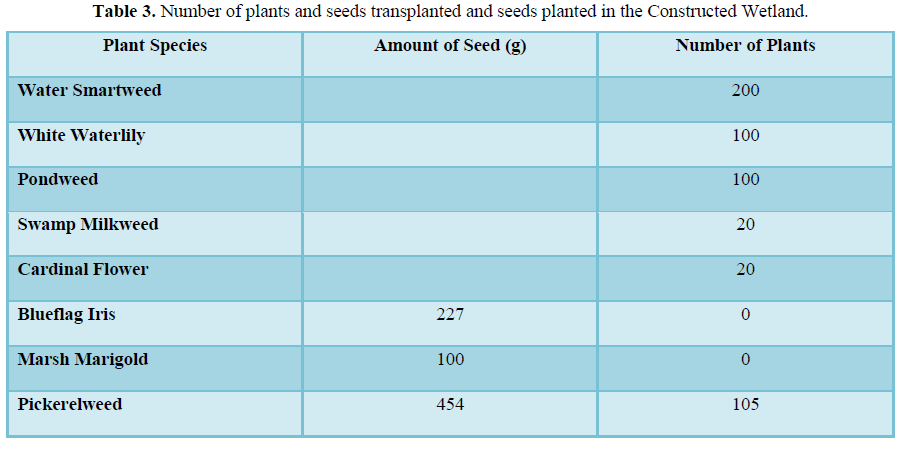

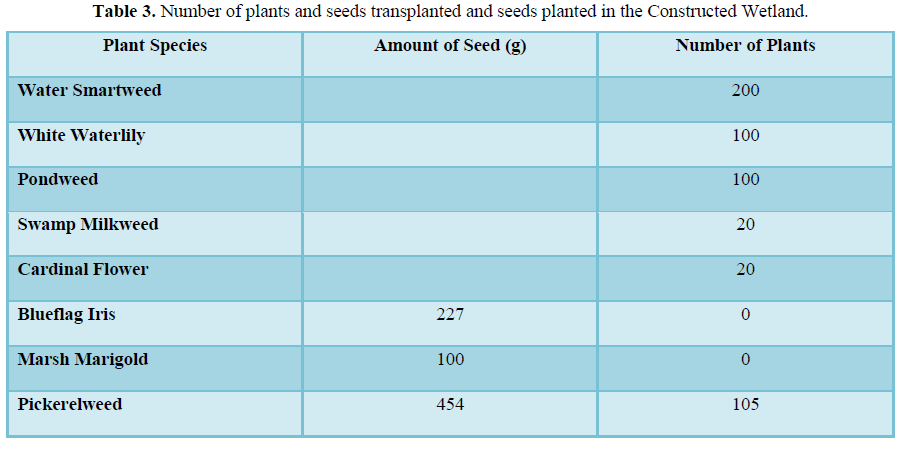

Five different plant species (Shasta Daisy, Yarrow, Lamb's Ear, Catchfly and Speedwell) were planted along the exterior berms of cells 1, 2, 5, 6, 7 and 8. In total 250 (50 for each species) plants were planted in early spring April), approximately 30 cm apart to give them the maximum potential of survival by decreasing interspecies competition. First, topsoil was placed on the exterior berms up to a depth of 20 cm. After planting, a mixture of mulch was dispersed along the exterior berms to reduce erosion, inhibit weed growth, and conserve the moisture. A total of 545 plants were transplanted and 781 grams of seed were planted into the internal area of the external berms of cells 1, 2, 3, 7, 8 and 9 and along berm 2, 3 and 7. The plants with the fewer flowers were strategically placed, whereas the plants with larger numbers of flowers were randomly placed to cover the entire desired area. Table 3 lists the total number of plants transplanted into and the number of seeds planted in the interior of the external berms of the Constructed Wetland in cells 1, 2, 3, 7, 8 and 9 and along berms 2 and 3. The seeds were mixed with small rocks and placed into a seed bag, then thrown into cells 1, 2, 8, and 9. Figures 10 & 11 show the grown vegetation on the internal and external berms.

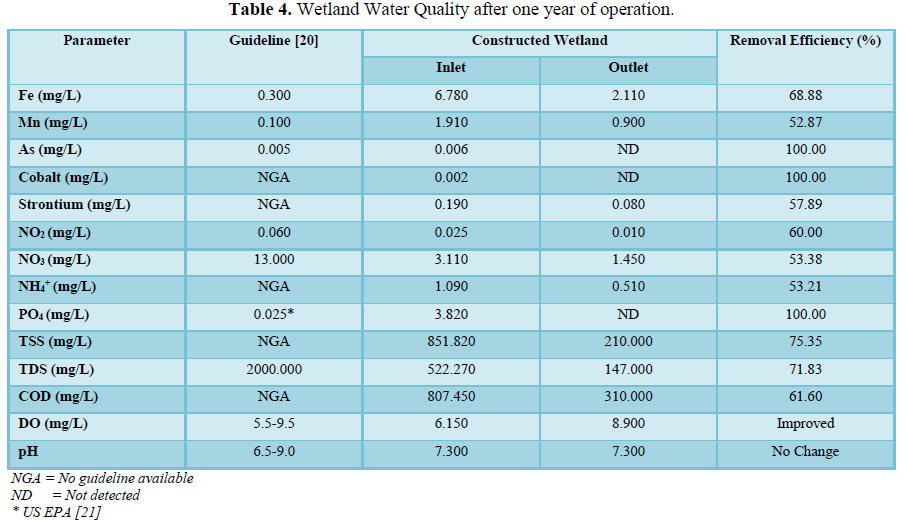

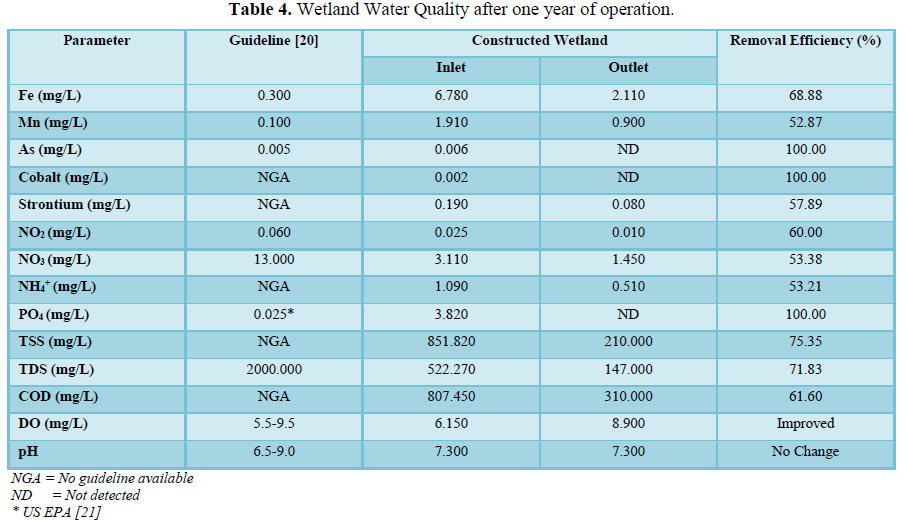

Water samples were collected from the wetland inlet and outlet in late fall (after plant grew and became stablished) and analyzed. The water quality is shown in Table 4. The engineered wetland achieved high reduction in all parameter tested after only one season. The removal efficiencies were 68.88 % for Fe, 52.87 % for Mn, 100.00 % for Co, 57.89 % for St, 60.00 % for NO2, 53.21 % for NO3, 53.21 % for NH4, 100.00 % for PO4, 75.35 % for TSS, 71.83 % for TDS and 61.40 % for COD. The DO improved (from 6.1 -8.9 mg/L) and the pH remained the same.

Trail and Bridges (Recreational Aspects)

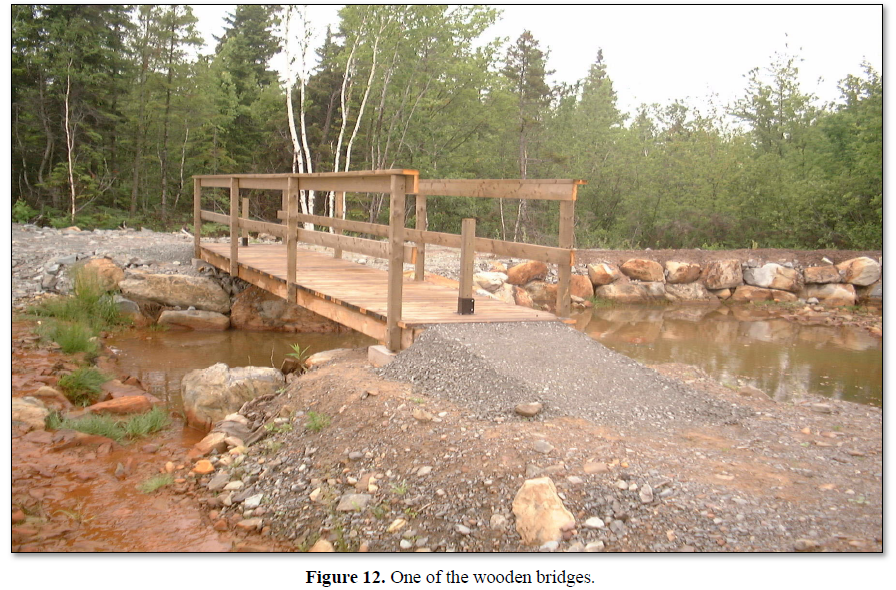

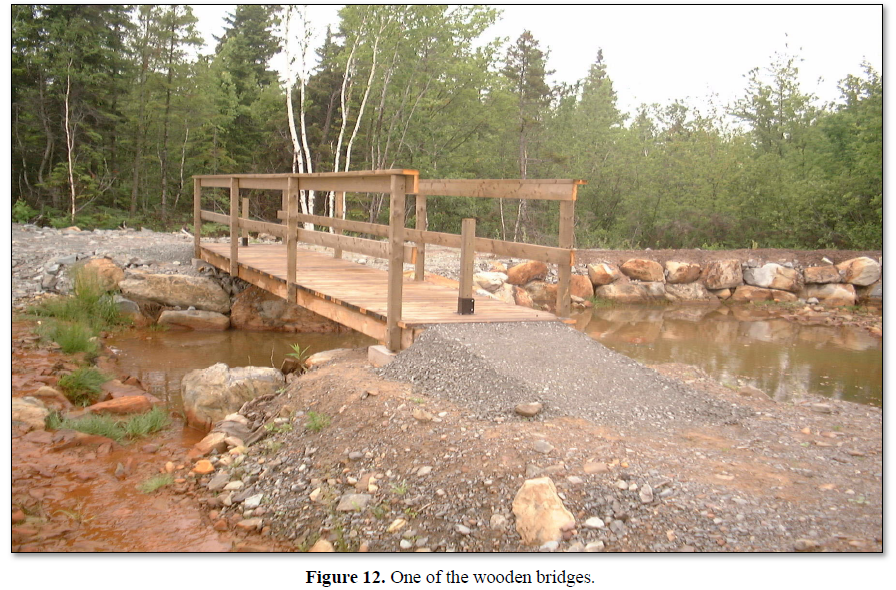

A trail in the shape of the letter eight was constructed in the Eco-Park (Figure 8) to provide a walking place for the employee of Burnside Industrial Park and the residence of Dartmouth North. The length of the trail was 8 km and the width was 4 m. It was constructed from gravels and shrubs and flowering plants were planted in both sides of the trail. Tow wooden foot bridges were constructed. The first bridge (Figure 12) spans a 25 ft length between cell 6 and cell 7 of the wetland and provides the public with a safe passageway to the new walking trail and access to a large area of the constructed wetland where the plastic sculpture and the solar operated model scale water purification system are located. The second wooden bridge was similar and was located at the end of the trail above the ditch near Enchanted Lake as shown in Figure 8.

Sculpture and Water Purification System (Cultural and Artistic Aspect)

The sculpture and water purification system (Figure 13) were constructed from recycled plastics. The filtration system is basically a mini wetland environment created with plastic structures located next to the sculpture.

Plastic elements in the work included plastic bottles, recycled resins, polystyrene, auto fluff, filter barriers, gas membranes and gas textiles. These materials were used as a soil substitute to sustain plant growth that will clean polluted water through a process known as phytoremediation. A solar power pump lift water from the inlet of Wright's Brook into the sculpture and the filtration systems. The waste plastic will function as a mechanical filter and the plants and microorganisms as biological filters retrieving waste, toxins and other impurities from the wastewater.

Rock Gardens (Botanicals Aspect)

A rock garden is an area of the landscape that is composed of rocks and plants. The types of plants most appropriate for rock gardens include many species which are native to the specific garden’s region. Rock gardens serve a variety purposes: (a) allow people to create and maintain a beautiful landscape, especially on steep slopes where grass is difficult to grow, (b) are an ideal way to prevent soil erosion, especially on sloped land, (c) allow gardeners to collect and learn to care for a variety of plants, (d) because the plants used in a rock garden are primarily small, many species can be accommodated in a limited area, (e) provide people with a hobby, which is not excessively demanding but requires reasonable dedication and attention and (f) can be used as an educational tool and a tourist attraction for the public.

Two rock gardens were constructed on the project site in the Burnside Industrial Park (Figure 14). First, a survey of the project site was conducted to decide on a suitable location for each rock garden. The sites selected have numerous natural rock formations which was advantageous because it limited the amount of heavy lifting and effort required to move large rocks. In the first rock garden, unwanted vegetation was removed by digging out all roots and tops. Red maple trees and shrubs including some blueberry bushes were preserved to: (a) provide shade for part of the day, (b) provide a source of food for wildlife and (c) act as a background for the garden. The second rock garden encompassed an area approximately twice the first garden. The existing unwanted vegetation was removed, and large toothed aspen trees were preserved. Topsoil was transported and spread throughout the gardens and around the existing rocks, shrubs, and trees to ensure that there was sufficient depth of soil to support plant growth.

Plants were bought from a local nursery and planted in each garden. Holes were dug at least twice as wide as the diameter of each plant’s root ball and deep enough so that

Plastic elements in the work included plastic bottles, recycled resins, polystyrene, auto fluff, filter barriers, gas membranes and gas textiles. These materials were used as a soil substitute to sustain plant growth that will clean polluted water through a process known as phytoremediation. A solar power pump lift water from the inlet of Wright's Brook into the sculpture and the filtration systems. The waste plastic will function as a mechanical filter and the plants and microorganisms as biological filters retrieving waste, toxins and other impurities from the wastewater.

Rock Gardens (Botanicals Aspect)

A rock garden is an area of the landscape that is composed of rocks and plants. The types of plants most appropriate for rock gardens include many species which are native to the specific garden’s region. Rock gardens serve a variety purposes: (a) allow people to create and maintain a beautiful landscape, especially on steep slopes where grass is difficult to grow, (b) are an ideal way to prevent soil erosion, especially on sloped land, (c) allow gardeners to collect and learn to care for a variety of plants, (d) because the plants used in a rock garden are primarily small, many species can be accommodated in a limited area, (e) provide people with a hobby, which is not excessively demanding but requires reasonable dedication and attention and (f) can be used as an educational tool and a tourist attraction for the public.

Two rock gardens were constructed on the project site in the Burnside Industrial Park (Figure 14). First, a survey of the project site was conducted to decide on a suitable location for each rock garden. The sites selected have numerous natural rock formations which was advantageous because it limited the amount of heavy lifting and effort required to move large rocks. In the first rock garden, unwanted vegetation was removed by digging out all roots and tops. Red maple trees and shrubs including some blueberry bushes were preserved to: (a) provide shade for part of the day, (b) provide a source of food for wildlife and (c) act as a background for the garden. The second rock garden encompassed an area approximately twice the first garden. The existing unwanted vegetation was removed, and large toothed aspen trees were preserved. Topsoil was transported and spread throughout the gardens and around the existing rocks, shrubs, and trees to ensure that there was sufficient depth of soil to support plant growth.

Plants were bought from a local nursery and planted in each garden. Holes were dug at least twice as wide as the diameter of each plant’s root ball and deep enough so that once the plant was placed in the hole, the top of the root ball was approximately at level with the ground. The original soil was blended with topsoil and peat moss and fertilized with bone meal to help the plants develop a healthy root system and then placed back in the hole around the plant. The soil was gently tamped down around each plant and then the plants were heavily watered. Finally, a layer of organic mulch composed primarily of bark was spread throughout each garden to: (a) reduce evaporation of water, (b) limit weed growth and (c) improve soil fertility upon decomposition.

Arboretum and Signage (Educational Aspect)

A procedure was developed to establish the arboretum area with potential walkways (Figure 9). The walkways were designed in a manner as to accentuate selected vegetation and physical land formations. Each walkway was designed according to the physical landscape and natural vegetation available in the area. The walkways are classified as woodland walkways as they will be covered with mulch produced from dead trees and/ or

purchased. The walkways will have interpretative signs that will provide information about native trees which will be of educational benefits to the public.

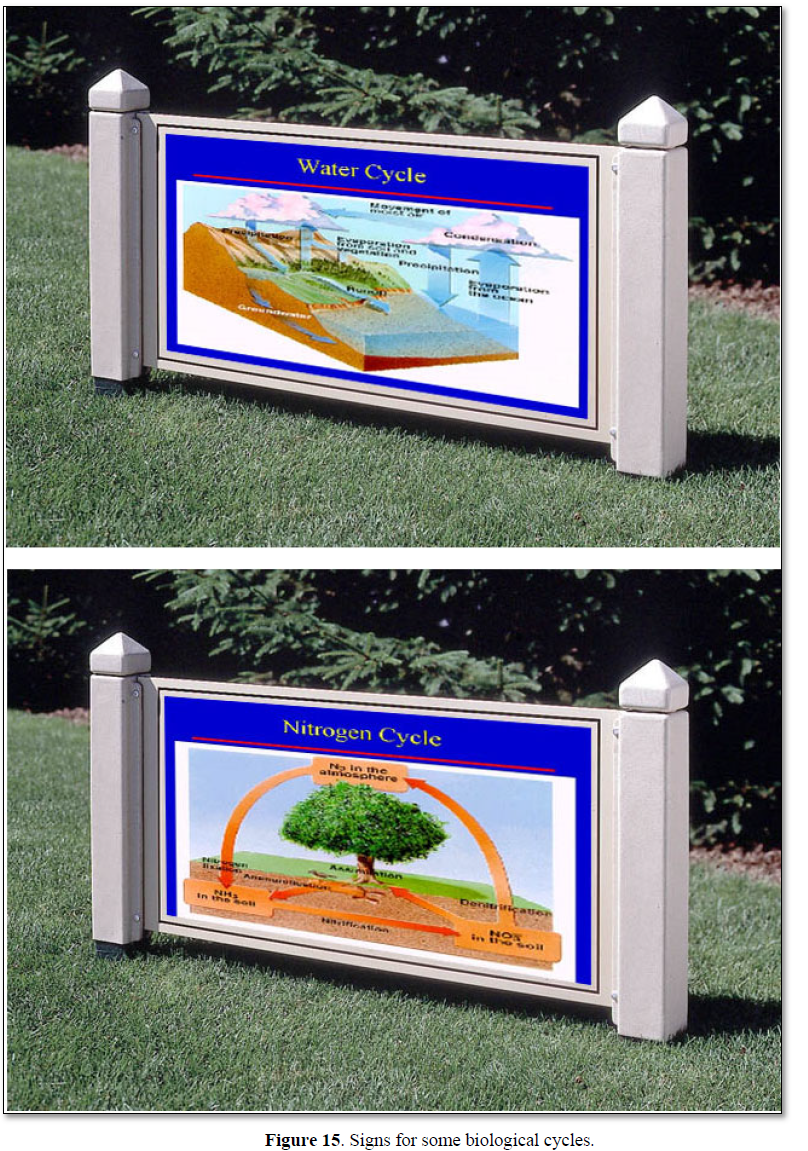

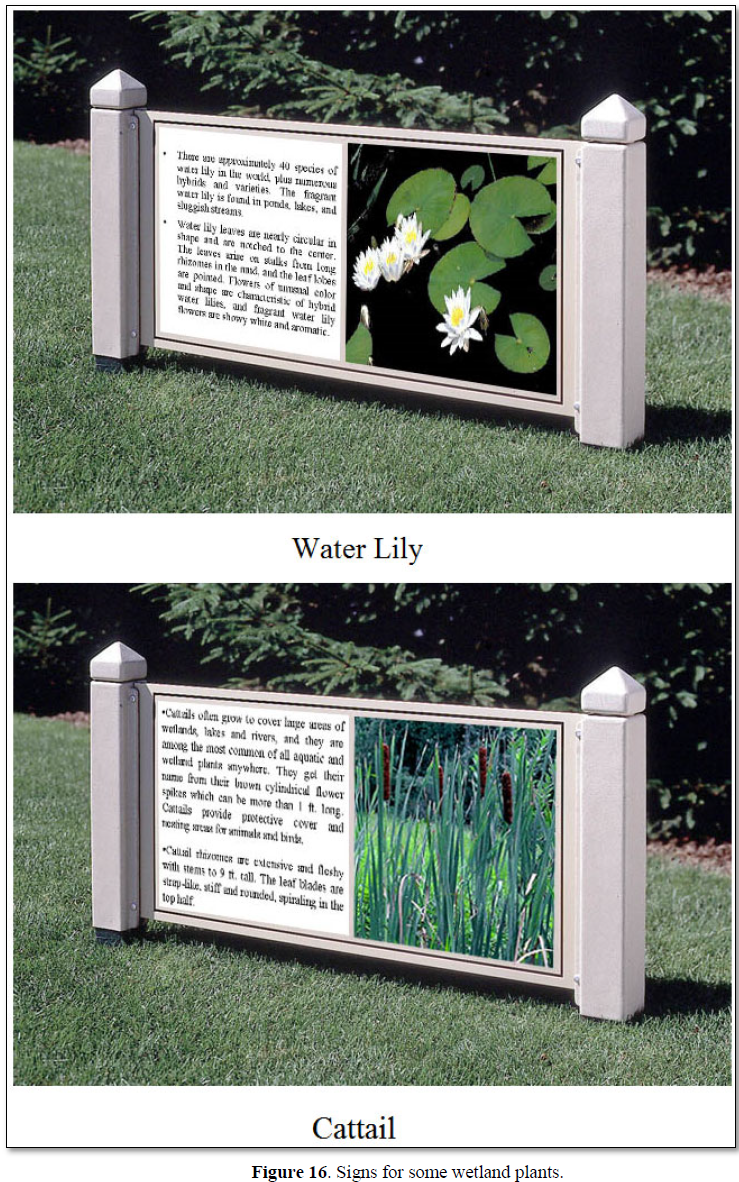

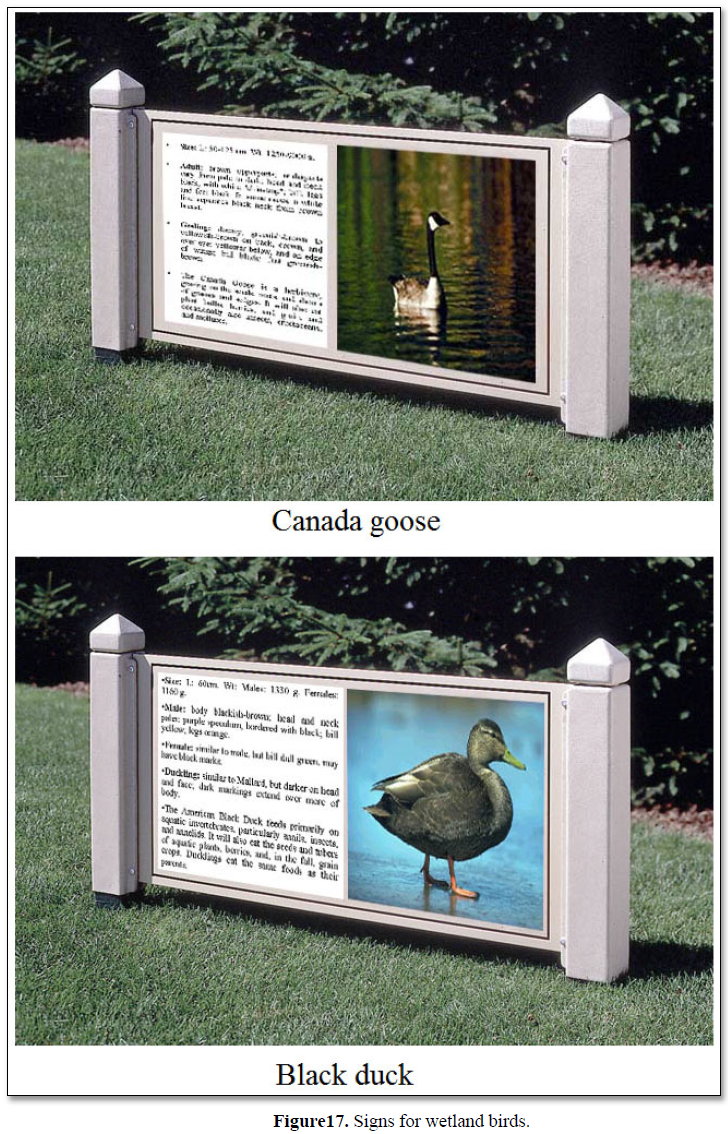

It is anticipated that the engineered wetland would be used as an outdoor classroom for elementary and secondary schools in biology and geography, as well as for environmental science and engineering classes in universities. A number of educational signs made of plastic will give educational information on environmental problems related to landfills and industrial parks, wetland biological processes, wetland plants and their functions and animal and birds living in wetlands (Figures 15-18).

CONCLUSIONS

Industrial parks are becoming more noticeable features of the Canadian and global landscape. Due to their improperly planned construction and the nature of the industries located in them, some parks are blights in the landscape with attendant health and environmental impacts. Our work has demonstrated that this does not have to be the case. With the support of municipal and provincial governments and private organizations, industrial parks can and should be designed and operated in a manner which is more compatible with natural and cultural amenities of an area. This project succeeded in protecting natural waterways and fostering environmental awareness through technical, cultural, and artistic expressions. A 21- acre eco-park that includes an engineered wetland, trails, picnic areas, educational signage, sculpture, an arboretum, rock gardens and bridges was developed. In addition to the wetland treatment facility, the park is intended to used as an educational and recreational facility as well as a tourist attraction.

ACKNOWLEDGEMENT

This project was funded by Environment Canada Eco-Action Community Program, Environment Canada Environmental Damage Fund Program, ELJB Foundation, TD Friends of the Environment Foundation, Halifax Regional Municipality and Natural Resources Canada.

-

UNEP (1997) Technical Guide to Environmental Management of Industrial Estates. United Nations Environmental Program, United Nations, Washington, DC, USA.

-

Cote RP, Cohen-Rosenthal E (1998) Designing eco-industrial parks: a synthesis of some experiences. J Clean Prod 6(5-6): 181-188.

-

Peddle MT (1993) Planned industrial and commercial developments in the United States: A review of the history, literature and empirical evidence regarding industrial parks. Econ Dev Q 7(1): 107-124.

-

Cote RP, Hall J (1995) Industrial parks as ecosystems. J Clean Prod 3(1,2): 41-46.

-

Lowe E, Moran S, Holmes DA (1995) Field book for the development of eco-industrial parks. Report for the U.S. Environmental Protection Agency, Indigo Development International, Oakland, California, USA.

-

Ayres RU (1995) Industrial metabolism: Theory and policy. In: The greening of industrial ecosystems (Richards, D. J., B. R. Allenby and R. A. Frosch, Editors). National Academy of Science, Washington DC, USA.

-

Anh PNN (2018) Impacts of industrial zones on the socio-economic development of Binh Duong province. PhD Thesis, Binh Duong University of Economics, Binh Duong Province, Vietnam.

-

Anh VTK, Ha HTV, Ha DT, Chio NTD (2019) Impacts of industrial zones on the socio-economic development: Experimental research in the Thai Binh Province Vietnam. Acad Account Financial Stud J 23(4): 1-19.

-

TNO (2020) Environmental impact around Industrial parks. Environmental Health and Safety Report, Netherlands Organization for Applied Scientific Research, Laan, vanWestenenk, Apeldoon, The Netherlands. Accessed on: October 28, 2020. Available online at: tno.nl/media/2738/004e_bo_mil_bo¬environmental_impact.pdf

-

Allen DT, Behmanish N (1994) Wastes and raw material. In: Allenby BR, Richards DJ, editors. The greening of industrial ecosystems. National Academy Press, Washington DC, USA.

-

Bunge J, Cohen-Rosenthal E, Ruiz-Quintanilla A (1996) Employee participation in pollution reduction: preliminary analysis of the Toxics Release Inventory. J Clean Prod 4(1): 9-16.

-

Ghaly AE, Cote RP (2002) Engineered wetland for treatment of industrial park contaminants. Report for Eeco-Action community Funding Program, Environment Canada, Dartmouth, Nova Scotia, Canada.

-

Bunge, J., E. Cohen-Rosenthal, A. Ruiz-Quintanilla. 1996 Employee participation in pollution reduction: preliminary analysis of the Toxics Release Inventory. Journal of Cleaner Production, 4(1):1-12.

-

Ghaly AE (2000) Phytoremediation of Polluted Ecosystems. Paper presented at the CCMC/NATO Workshop on Management of Toxic Wastes and Substances, Ioannina, Greece.

-

Roberts B (2004) The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: An Australian case study. J Clean Prod 12(6): 997-1010.

-

Al-Wahaibi A, Zeka A (2015) Health impact from living near a major industrial park in Oman. BMC Public Health 15: 524.

-

Dellantvono N, Carbonara N, Pontrando P (2017) The organization of eco-industrial parks and their sustainable production. J Clean Prod 161(2): 368-375.

-

UNEP (1997) The environmental management of industrial estates. Industry and Environment Technical Report No. 39. United Nations Environmental Programme, Paris, France.

-

EC (2020) Average monthly runoff for the four watershed areas for the period of 1970 - 2020. Shearwater A Weather Station, Environment Canada, Dartmouth, Nova Scotia, Canada.

- CCME (2006) Canadian water quality guidelines for the protection of aquatic life. Summary table. Canadian Council of Ministers of the Environment, Winnipeg, Manitoba. Accessed on: July 24, 2020. Available online at: http://www.ccme.ca/assets/pdf/ceqg_aql_smrytbl_e_6.0.1.pdf

-

US EPA (2018) National Recommended Water Quality Criteria - Aquatic Life Criteria. Environmental Protection Agency, Washington DC, USA.