689

Views & Citations10

Likes & Shares

The current review paper illustrated the

invention in estimation of Fluorspar method; it is commonly used for slag

making in steel industry, glass manufacturing and high purity acid grade in

nuclear process. In the last centuries significant research efforts have been

done for the analysis of fluorspar on industrial basis but still CaF2

has been analyzed by classical method and no quick method is available.

Fluorspar mainly consists of SiO2, CaO, Al2O3,

BaO and CaF2. At present, we have developed X-ray fluorescence

method and in current review we emphasize and compare the mineralogical

contents of fluorspar estimated by conventional method and new advance method.

Keywords: CaF2, WDXRF method Conventional method, CS analyzer

INTRODUCTION

History and etymology

Fluorite is Latin word noun, fluo, means continuous

with flow like water flow. In verb present as fluor or fluere, is stated as

flow. The CaF2 is utilized as flux in steel making process to

increase the fluidity of slag or we can say decrease the viscosity. Calcium

fluoride melts at 1676 K. The word flux extracted from Latin word noun fluxes.

German scientist Agricola having expertise in philology, mining and metallurgy

termed as fluorspar as Neo Latinization of the German Flussespar from Flusse

(stream, river) and “Spar” (meaning a nonmetallic mineral akin to gypsum,

spærstān, spear stone, belong to name crystalline (Picture 1) [1,2].

Fluorite is called as fluorspar is a halide consists

of CaF2. Calcium fluoride is an isometric mineral with a cubic

structure with octahedral and other complex isometric shapes are not

occasional. CaF2 is a colorful mineral having with visible

ultraviolet light and it is used as ornamental and lapidary. Fluorite is

commonly used in industry as a source of flux for smelting, glasses production

and enamels. High quality CaF2 grades are used a source of fluoride

for HF acid manufacturing. It is also used source as intermediate fluorine

containing fine chemicals. By using fluorite prepared low dispersion lenses for

far ultraviolet region mostly used in microscope and telescopes.

Calcium fluoride inorganic compound consist of

calcium and fluorine having formula CaF2 and F-centrally coordinated

with 04 Ca2+ centers [4]. Crystalline samples of CaF2 are

mostly colorless and some are deep color due to F- presence in center. The few

crystal presence in numerous ionic compounds with CeO2, ZrO2,

etc.

Occurrence

Fluorite is broadly presence

mineral in huge deposits in much area. Significant occurrence areas in China,

Germany, Austria, Switzerland, England, Norway, Mexico and both the Province of

Ontario and Newfoundland and Labrador in Canada. Large deposits also occur in

Kenya in the Kerio Valley area within the Great Rift Valley. In Pakistan, Fluorspar

is majorly present in Loralai, etc.

APPLICATION, SOURCE OF FLUORINE

AND FLUORIDE

High purity grade is manufactured by combination with calcium carbonate and hydrofluoric acid [5].

CaCO3 + 2 HF → CaF2 + CO2 +

H2O

Fluorite is a main source of

hydrogen fluoride [6]; it is commonly used for the production of wide range of

materials. HF is evaluated from mineral by the reaction with concentrated

sulfuric acid.

CaF2(s) + H2SO4 → CaSO4(s)

+ 2 HF (g)

The produced HF is converted into fluoride, fluorocarbons and produced different materials. In 1990s annually production of CaF2 is five billion kilogram. There are three main type of natural fluorspar used in industries. Metallurgical grade fluorite (60-85% CaF2), Ceramic grade fluorite (85-95% CaF2) and highest grade, “acid grade fluorite” (97% or more CaF2), accounts for about 95%.

Metallurgical grade has been

used traditional as flux; ceramic grade is used in the manufacturing of glass,

enamels and cooking utensils. Acid grade used to make hydrogen fluoride and

hydrofluoric acid and traditionally by reaction with fluorite with H2SO4

[7,8].

ESTIMATION OF FLUORSPAR BY

DIFFERENT SCIENTIST

Calcium fluoride contents

were determined by EDTA in iron tailings. The samples were prepared by diluted

acetic acid to leach calcium carbonate. The contents of CaF2 consist

of two parts one fluoride contents were illustrated by zirconium xylenol orange

by spectrometer after CaF2 was filtered according to these values

concentration of CaF2 were calculated and other practice of CaF2

by leaching as precipitating with leaching aluminum chloride solution for

titration calcium indicator used as indicator EDTA standard titration solution

was used to determine for precipitation of CaF2 in KOH medium.

Therefore CaF2 contents were calculated by values. This illustrated

method was simple, rapid, précised and recovery could meet the requirements in

the CaF2 determination the standard deviation was less than 1% and

recovery 99-101% [9].

The invented method is for

the quantitative determination of calcium fluoride by EDTA titration. Take

0.2-0.50 g sample material into beaker then added HCl and boric acid solution

heat and dissolved for 20-40 min filter sample and collecting filtrate wash

precipitates present beaker cool and added water. If barium is present in

sample <0.2 wt%, it is precipitating out taking out 10-20% filtrate in

beaker with 80-100 ml water and used triethanolamine with KOH to maintained pH

grater then 13 and titrate with EDTA standard solution in the presence of mixed

indicator. In case of barium grater then >0.2 wt%, aliquot 10-20% of

filtrate in beaker adding 40-50 ml introduce 2-5 drops sulfuric acid and boil

10-20 min and hold grater then 8 h and collect filtrate in another beaker

washing the original beaker ppt and maintained filtrate volume 80-120 ml and

add tri-ethanolamine maintained pH by using KOH gratering grater then 13,

titrate with EDTA with mixed indicator.

In first step weight

0.20-0.30 g and 0.40-1.20 g samples material in two beakers then add HCl-H2SO4

solution hold at room temperature for 40-60 min and shake 3-50 min till ppt

fully dispersed, 1-3 drop phenolphaline indicator and adding KOH the reddish

color this process continue till HCL reddish color disappears, transfer

solution in volumetric flask and fill with water and hold for 8 h then pipette

out 30-50% and repeat same procedure after end of titration calculate non

calcium fluoride calcium content in sample by using two volume difference and

weight difference of sample materials. The mixed indicter is mixture of calcium,

European Pharmacopoeia Reagent and potassium chloride. The invented method has

precise and CaF2 calculated values are authentication.

Fluorite powder directly

analyzed by XRF after pressed pellet combination with spectroscopy, the total

content of Ca and content of Fe2O3, P, SiO2

and K2O as well as carbon present in sample analyzed by IR

absorption spectrometer and carbon content calculated as CaCO3 then

CaF2 calculated content in fluorite. For estimation of unknown

samples the working curve was made using nine certified reference material the

method is accurate and further verification an accuracy standard (GBW07254) was

used to test accuracy and precision of method and found results satisfactory

[10].

Analysis of fluorspar by

traditional method after separating calcium carbonate and calcium fluoride it

takes longer time and not suitable for production but accuracy of results from

this method is very high. The publisher was illustrated two methods, alkali

fusion and acid leaching method. The operation analyzing results of this method

was very easy and short time for completion of analysis and observed that

results were accurate and it could be used for quick analyzing before

production.

The fluorite standards

prepared in group and samples with binder formed in the form of pressed pellets

method. These press pellets analyzed by x-ray fluorescence spectrometer and

obtained liner regression line. Curves after deduction of enhanced absorption

and spectral line overlap interference determine the content of pressed pellet

by using curve and calculate the fluorite by analysis of the corresponding

relation of spectral line intensity and concentration. The standards samples

and binder after sieving 300 mesh formed press pellet by using palletizer. This

creative method is rapid and accurate and can reduce the estimation cost and

enhance the detection limits. [11].

Other method for estimation

of calcium fluorite as CaC2 with diluted acetic acid. CaF2

cannot dissolved in acetic acid therefore sample was treated with acetic acid

and insoluble material filtered by filter paper then introduced potash solution

till pH attain 13 or greater than 13. CaC2 was determined by EDTA

titration method. Insoluble filtered material and filter paper was burned in

platinum crucible and added mixed flux with boric acid melt at 950°C than

acidify and added potash solution till pH 13 or greater and analyze CaF2

with EDTA titration. The RSD value of CaC2 was 0.064 and 0.01916%

and CaF2 RSD value observed 0.6285 and 0.8357%.

Fluorspar contents like CaF2,

SiO2, Al2O3 and total iron (TFe) are

calculated by XRFS. The samples were prepared by 1 g of sample and fusion

mixture KNO3 (0.2 g), Li2CO3 (1.0 g) and Li2B4O7

(5.0 g) in a Pt crucible and after addition of 3 drops of 150 g/L-1

LiBr solution, the mixture was fused at 1050° for 20 min. after cooling the 4

components were estimated. Samples present with reductive substance the fusion

method should be modified. Li2B4O7 put in the platinum

crucible after melting coated on inner wall of crucible at lower and bottom

side. After cooling, KNO3 and Li2CO3 added to

the crucible and peroxide at low temperature and fused sample as same

procedure. The melt sample was used for detection of 4 components. Working

curve prepared and used for estimation of results. Four samples were analyzed

by said method and giving results has consistency with results [12].

Review on new published paper

“Quantification of Metallurgical Flux by Wavelength Dispersive X-ray

Fluorescence” this advance test method was developed for the quantification of

fluorspar (CaF2) along with other present ingredients especially

trace elements like Ba, Sr, P and Mg. All above reported abstract showed that

few methods are invented in which analysis of fluorspar has carried out

partially and did not emphasize on complete chemistry of fluorspar. It can only

analyze Si, P, K, Na and other elements Ca soluble and total were analyzed by

classical methods.

The current established

method can analyze necessary elements by WDXEF and carbon was analyzed by

carbon sulphur analyzer as well as presence of CO2 as CaCO3

was confirmed by using ATR-FTIR and XRD method.

EXPERIMENTAL

Estimation of minerals XRF

WD-XRF- Philips Axios Max,

3KW Rhodium tube as X-ray generator along with crystals, channels and

collimator mask was used for creation of application and analyze standards and

unknown samples. Carbon was analyzed by CS-800 (Eltra) analyzer [12].

STANDARDS AND CALIBRATION

Initially calibration lines

of SiO2, Ca, P, SrO, BaO, Fe2O3 were developed

in WDXRF with known chemical composition of primary standards as well as

synthetic standards and same standards except synthetic standards were utilized

for carbon development calibration line in CS-800 analyzer. The following

primary standards were used for calibration of lines i- JK S9, ii- NCS DC

14023, iii- NCS DC 14025, iv- NCS DC 62003a, v- HJ-CGL 101, vi- UNS LAB

Fluorite FM, vii- ICRM-5132-89, viii -JK S10, ix- BCS 392 as well as utilized

high purity analytical reagents of silica (SiO2), calcium oxide

(CaO), calcium fluoride (CaF2), aluminum oxide (Al2O3),

magnesium oxide (MgO) and ferric oxide (Fe2O3) for

synthetic standards (Table 1).

SAMPLES OCCURRENCE AND

COMPOSITION

40

samples were collected by random sampling from different locations of Pakistan

Jurassic Loralai limestone of Gadebar, Daman Ghar, tor Thana, Wategam, Mekhtar,

Balao, Mahiwal areas of Loralai District. The fluorite of Loralai area occurs

as veins and as disseminated grains along faults and fractures which is hosted

by the Jurassic Loralai limestone forming the anticlinal core. Fluorite has

many colors such as pink, blue, light-grey, green and light-yellow (Picture 2).

Chemical analysis shows CaF2 varies from 95.20-95.40%, CaCO3

from 3.20-3.40% and SiO2 from 1.40-1.44%. Average weight %

concentration of Ca is 49%, F is 45%, SiO2 is 2.30%, CuO is 0.5%, Al2O3

is 2%, Fe2O3 is 0.08% and LOI is 1.47%. This type of

fluorite can be used for acid preparation and also as gemstones.

Homogeneity of

samples through grinding method, grinding time, mesh size, pelletized force

binder type and ratio. After said process samples passed through 150 µm and

oven dry at 105°C for 24 h and observed lose 0.001-0.10%.

CARBONATES

CONFIRMATION BY VOLATILIZATION, ATR-FTIR AND XRD PROCEDURE

CaF2

mineralogy having major compound of CaCO3 with respect to other

carbonates. This was confirmed by volatilization method at different

temperatures. The decomposition temperatures showed that calcium carbonate is

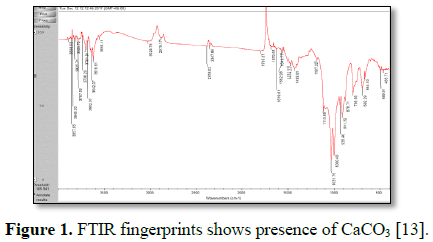

present as main constituent as well as presence of CaCO3 was

confirmed by Thermo Nicolet iS5 FTIR (Figure 1) with ZnSe (refractive

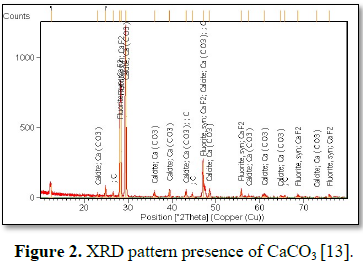

index 2.67) [14-19]. Mineralogy of compounds was determined by Expert Pro XRD

instrument which confirmed (Figure 2) the presence of CaCO3

instead of other compounds [20]. Carbon analyzed for estimation Ca by

mathematical calculation by IR method (Figure 3).

RESULTS AND

DISCUSSION

Why pressed sample instead of bead sample?

The published

application was particularly designed for all type of fluorspar in pressed

pellet samples. Fluorine has low molecular weight and decomposes during

825°C-1330°C [21].

Hence due to this

possible loss of fluorine may occur during calcinations. So, it is ineffective

to estimate by fused bead sample.

Mineralogy by XRD

Fluorspar samples

mineralogy were identified by XRD patterns and illustrated the presence of

alkaline earth carbonate as CaCO3 and CaF2.

FTIR illustrations

The characterized

FTIR confirmed the presence of CaCO3 in fluorspar. The presence of

infrared spectrum of the CaCO group starching of carbonates on 713, 875 and

1418-1473 cm-1 it shows the absorption bands of CaCO3

(Calcite) [22,23].

Analysis of carbon and CaF2

calculation

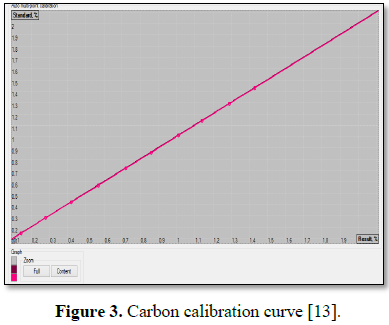

Total carbon in

certified reference material were used for calibration after analysis by

combustion method and observed regression factor R2=0.999 which

shows the linearity of calibration line. Theoretical carbon value was used for

calculation of CaCO3 present in standards samples the accuracy of

carbon direct related to CaF2.

The following

conversion factors used during development of application:

Total Ca to CaF2=

[Total Conc (“Ca”) - (Conc (“C”) × 4.665) × 0.715)] × 1.95

Apply factors during

application development

i- C to CaO=4.665; ii- CaO to Ca=0.715; iii- Ca to CaF2=1.95

Significant impact on method

The published

application quantify the concentration as total carbonates in the presence of

other carbonates such as Mg, Na and Ba, etc., instead of CaCO3, the

developed method has limitation to distinguish/separate the carbonates attached

with alkali and alkaline earth metals other than CaCO3 and it cause

significant impact on method. The analysis by different techniques shows that

natural fluorspar has major contents of CaCO3 with respect to other

carbonates. Therefore on the bases of several analytical observations the

developed application has no significant impact in the presence of other

carbonates in minor quantity on estimation of CaF2.

Specificity of invention

The invented method

has less background corrections, line overlaps and measuring time with respect

to other developed methods and classical estimations. The primary and in-house

established standards have no interference to each other. The complete analysis

time for standard and sample was just 340 s.

Method validation

The current invented

method has been verified by method validation before implementation in

industry. For validation different statistical tools such as standard

deviation, recovery (R, %), relative percent difference (RPD, Eq. (1)),

instrument detection limit (IDL), limit of quantization (LOQ), method detection

limit (MDL) and uncertainty (Ua), were used. The same method was verified by

classical method and observed that both values were approximately same.

RPD= 100 × (Value 2 - Value 1) / (Value 2 + Value 1)/2 (1)

Accuracy of fluorspar values

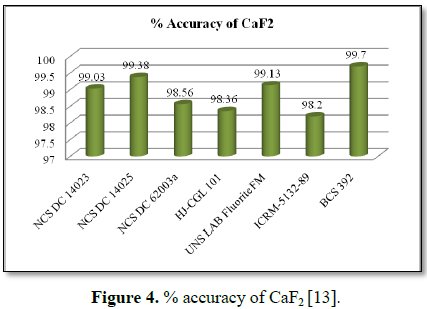

Accuracy of the CaO and CaF2

directly related to estimation of carbon observed values and values used in

calibration of carbon line (Figure 3). The accuracy of CaF2

primary certified standards results is illustrated in terms of bar chart (Figure

4).

Method validation and proficiency test results

This commercial method has

also verified by the proficiency test method. The proficiency results (Table

2) shows that invented method is used as commercial for all type of

fluoride grades and accurate for determination of CaF2.

Novelty of work

How we can say the published

work is novel as compare to classical and other published methods? On the basis

of significant of current work with respect to non-hazardous, time saving,

customer beneficial, industrial application and less error observed values of

standards and samples with related classical method and minimum z-score and

statistically significant Accuracy and

precision of the results obtained through invented method was more consistent

as compared to other method due to less human influence.

CONCLUSION

This paper “Quantification of metallurgical flux by wavelength dispersive x-ray fluorescence” was selected as a review of the method advancement in the field of inorganic chemistry.

Before said method

the CaF2 was estimated by classical method as described in American

standard testing method (ASTM-E1506) and some other methods have developed for

estimation of fluoride by combination with classical and instrumental

techniques but still not used in industry.

The published method

is advanced methodology for the determination of fluoride by instrumental

technique. It is the first step towards the novel development in short term

technique, improved performance and less hazardous with respect to classical

method. Finally by taking an overview of the current technique it is strong

support to analyst with confidence and opportunity towards the new approach in

the field of chemistry. At present we have further modify the published method

and can analyze complete estimation with WDXRF without using carbon analyzer.

ACKNOWLEDGMENT

The authors are highly grateful to “Mr. Syed Sajid Hussain”, Peoples Steel Mills Ltd for help in analysis.

1. Douglas

H. “fluorite”. Online etymology dictionary. Available at: https://www.etymonline.com/word/fluor

2. Douglas

H. “spar”. Online etymology dictionary. Available at: https://www.etymonline.com/word/spar

3. Hurlbut

CS, Klein C (1985) Manual of Mineralogy (after James D Dana)/Cornelis Klein,

Cornelius S Hurlbut Jr. 20th Edn, pp: 324-325. ISBN 0-471-80580-7.

Available at: https://trove.nla.gov.au/work/8455391

4. Miessler

GL, Tarr DA (2003) Inorganic Chemistry. 3rd Edn. Pearson/Prentice

Hall Publisher. Available at: https://www.amazon.ca/Inorganic-Chemistry-5th-Gary-Miessler/dp/0321811054

5. Aigueperse

J, Mollard P, Devilliers D, Chemla M, Faron R, et al. (2000) Fluorine

Compounds, Inorganic. Wiley Online Library. Available at: https://onlinelibrary.wiley.com/doi/full/10.1002/14356007.a11_307

6. Aigueperse

J, Mollard P, Devilliers D, Chemla M, Faron R, et al. (2005). Fluorine

Compounds, Inorganic. Ullmann's Encyclopedia of Industrial Chemistry. Weinheim:

Wiley-VCH.

7. Wiberg

E, Wiberg N, Holleman AF (2001) Inorganic Chemistry. Academic Press: San Diego.

Available at: https://www.worldcat.org/title/inorganic-chemistry/oclc/48056955

8. Michael

MM (2009) Fluorspar. USGS Minerals Yearbook. Available at: https://minerals.usgs.gov/minerals/pubs/commodity/fluorspar/myb1-2009-fluor.pdf

9. Yang

C, Chaoyan C (2016) Determination of CaF2 in iron ore tailings by EDTA

complexometric titration. Chinese Journal of Inorganic Analytical Chemistry 6:

20-24.

10. 10.

Xian Y (2014) Analysis of component in fluorite using pressed powder pellet

x-ray fluorescence spectrometry combined with infrared spectroscopy. China

Inorganic Analytical Chemistry 4: 50-52.

11. Ma A,

Feng S (2012) Method of measuring component contents in fluorite by applying X

fluorescence powder tablet pressing method. Faming Zhuanli Shenqing CN

102809578.

12. Li S,

Du C, Zhang H (2011) Determination of TFe, SiO2, P, CaO, MgO in

sponge iron by x-ray fluorescence spectrometry. Lihua Jianyan Huaxue Fence 47:

1162-1164.

13. Akhter

N, Mumtaz M, Hussain SS (2018) Quantification of metallurgical flux by

wavelength dispersive x-ray fluorescence. Chem Sci J 9: 1-17.

14. Nishikawa

M, Batdorj D, Ukachi M, Onishi K, Nagano K, et al. (2013) Preparation and

chemical characterisation of an Asian mineral dust certified reference

material. Anal Methods 5: 4088-4095.

15. Maitra

S, Chakrabarty N, Pramanik J (2008) Decomposition kinetics of alkaline earth

carbonates by integral approximation method. Ceramica 54: 268-272.

16. Valverde

JM, Perejon A, Medinac S, Perez-Maquedad LA (2015) Thermal decomposition of

dolomite under CO2: Insights from TGA and in situ XRD analysis. Phys

Chem Chem Phys 17: 30162-30176.

17. Mazzeo

R, Joseph E, Prati S, Millemaggi A (2007) Attenuated total reflection Fourier

transform infrared microspectroscopic mapping for the characterization of paint

cross sections. Analytica Chimica Acta 599: 107-117.

18. Zhang

WR, Lowe C, Smith R (2009) Depth profiling of coil coating using step-scan

photoacoustic FTIR. Progress in Organic Coatings 65: 469-476.

19. Stuart

(2004) Infrared Spectroscopy: Fundamentals and Applications B. John Wiley &

Sons, Ltd ISBNs: 0-470-85427-8 (HB); 0-470-85428-6 (PB).

20. Pandey

GC, Kulshreshtha AK (1993) Fourier transform infrared spectroscopy as a quality

control tool. Process Control and Quality 4: 109-123.

21. Schmidbaur

H (1985) Greenwood VNN, Chemistry of the Elements. Von N. N. Greenwood und A.

Earnshaw. Pergamon Press, Oxford 1984, 1542 S., geb. $ 95.00. ‐ ISBN

0‐08‐022056‐8; Paperback $34.95: ‐ ISBN 0‐08‐022057‐6. Wiley Online Library.

22. Meejoo

S, Maneeprakorn W, Winotai P (2006) Phase and thermal stability of nanocrystalline

hydroxyapatite prepared via microwave heating. Thermochimica Acta 447: 115-120.

23. Ratner

B, Hoffman A, Schoen F (2004) An Introduction to Materials in Medicine. In:

Biomaterials Science. 2nd Edn. Academic Press, p: 851.