964

Views & Citations10

Likes & Shares

High voltage electric field (HVEF), as a

novel technique, has recently been known in food industry because of its low

thermal damage, being free of chemicals, low energy consumption, non-mechanical

design, simplicity and rapid control. High voltage electric field thawing, as a

quick method, has been paid a lot of attention in recent years. In this

technology, an electrical wind is produced by the corona discharge, air is

ionized and ions produced in a small area around the needle electrodes, are

then accelerated by an electric field and the resulting momentum is transferred

from the air ions to the neutral air molecules to move the bulk fluid towards

the surface. Different electrode configurations such as point-ring,

needle-ring, needle-plane and wire-plane are commonly used for preparing

electric field. As review of studies suggests the thawed food under HVEF showed

better quality characteristics than the one thawed under conventional thawing

such as still air method. However, high electric field strengths may have

adverse effects on the structure and physical properties of the product.

Decrease in thawing time and energy consumption has been reported, too.

However, achieving the best quality of HVEF thawed products depends on the

electric field condition like electrode distances, electrode spacing between

the two neighboring needles, voltage and electric field strength. This paper

describes and deals with the HVEF technique and its applications in thawing of

food.

Keywords: High voltage electric field, Thawing, Corona discharge, Electrode

distance, Voltage

INTRODUCTION

Today, non-thermal techniques have been

noticed in order to overcome the problems caused by conventional thermal

processes and their associated long process times. High voltage electric field (HVEF)

is one of the recent non-thermal technologies. In this method, air is ionized

in a needle-plate electrode system by a corona discharge. One of the effects of

the corona discharge is the generation of an electric field-induced flow or

secondary electrohydrodynamic flow (EHD) which is produced by transferring momentum

from high speed drifting ions to surrounding air molecules [1]. HVEF is

advantageous for its low energy consumption, non-mechanical design, simplicity

and rapid control. HVEF has been mostly applied for the drying of foods [2,3],

preserving food freshness through increasing its shelf-life [4-6]. It also

controls ice nucleation [7-9] and inhibits microbial growth [10,11]. Recent

studies have been conducted towards the use of electric field in thawing,

described below.

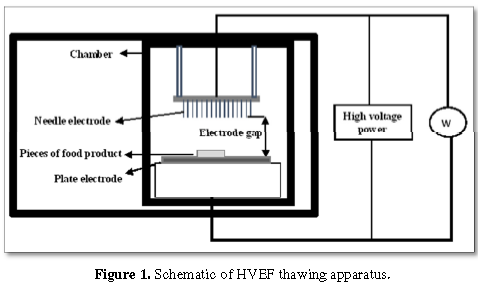

HVEF process mechanism

HVEF process is based on the production of an

electrical wind by corona discharge. Corona discharge involves the partial

electrical breakdown of the gaseous medium between at least two electrodes: a

sharp electrode with very small radius of curvature which is called the corona

electrode or emitter electrode and could be wires, pins and needle and a blunt electrode

with much larger radius of curvature which is grounded (grounded electrode).

Different electrode configurations such as point-ring, needle-ring,

needle-plate and wire-plate are commonly used for preparing electric field. The ions produced in a

small area around the needle electrodes are then accelerated by an electric field and the

resulting momentum is transferred from the air ions to the

Application of HVEF in thawing

Thawing generally occurs more slowly than freezing; therefore, there is

a possibility of further damage to the product following chemical and physical

changes [13]. On the other hand, increasing surface temperature results in

possible microbial growth on the product surface [14]. Leaching of soluble

nutrients, particularly proteins, and large quantities of loaded waste-water

are also other disadvantages of conventional thawing [15]. Thus, it seems by

applying non-thermal and fast techniques, these problems can be overcome. One

of the new applications of HVEF involves thawing of food. Recent studies have

shown that thawing of food by HVEF reduces damages occurring during the process

because of the reduction of the process time and the antimicrobial effects of

HVEF thawing [11,16-18]. Basically, the initial temperature in the thawing

process of a frozen material changes very fast up to a temperature of ‒5°C.

However, the rise in temperature up to 0°C accounts for the longest thawing

time. The temperature range between ‒5 to 0°C is often considered to be the

maximum ice formation zone in food freezing and HVEF has its greatest impact on

this temperature range [13].

Bai et al. [19] investigated the optimal parameters involved in thawing

with an electrical field. They estimated the effects of the distance between

the two neighboring needles, the electrode spacing and different thawing

voltages on the thawing rate and energy consumption.

Their results showed that 9 cm electrode spacing fewer than 6 cm

distances between the two neighboring needles at the voltage of 45 kV yielded

the maximum thawing rate and little electrical energy. Moreover, they indicated

that energy consumption and thawing rate increased sharply when voltage

exceeded 25 kV. Finally, they concluded 45 kV was the optimum thawing voltage

due to its largest thawing rate and relatively low energy consumption [19].

Hesie et al. [11] studied the effect of thawing by HVEF on the qualitative

properties of frozen chicken. They applied 20 kV on 16 negative needle

electrodes at an electrode gaps of 20 cm. Thawing was accomplished in the

temperature range of ‒3°C to 4°C and reduced the thawing time up to 0.66 and

0.75 of a traditional thawing. Microbial counts, total volatile basic nitrogen

and weight losses decreased compared with the control, but water holding

capacity of the protein of the HVEF-thawed chicken was greater. Another study

investigated the effect of HVEF treatment on the thawing characteristics and

post-thawing quality of frozen pork tenderloin meat. In this study, 16 needle

electrodes, 0.001 mm in diameter, were used and voltages of 4, 6, 8 and 10 kV

were applied at a temperature of 20°C for meet thawing. The thawing times

recorded were 52, 46, and 40 min for the voltages of 6, 8 and 10 kV,

respectively. The time taken for thawing of the control sample [still air thawing]

was 64 min, while the 4 kV treatments recorded a longer thawing time than that

of the control. Furthermore, it was found out that HVEF led to a reduction in

microbial counts and total volatile nitrogen compared to the control.

Nevertheless, high voltage treatment led to a greater weight loss and cooking

loss due to thawing [16].

He et al. [20] examined the factors affecting the thawing

characteristics and energy consumption of frozen pork tenderloin meat using

high-voltage electrostatic field. The thawing time of the frozen pork was

shortened by increasing the voltage and decreasing the electrode distance, but

this shortening was limited above a certain voltage under a particular

distance. On the other hand, the energy consumption for HVEF thawing was very

low compared with microwave, hot- and cold-water thawing methods which means

HVEF-thawing is an energy-efficient and cost-saving method.

Mousakhani-Ganjeh et al. [17] investigated the impact of high voltage

electric field -thawing on frozen tuna fish quality. Their results demonstrated

that thawing rate increased with increasing the voltage and reducing the

electrode gap. The authors also declared that volatile nitrogen produced by

microorganism was reduced; however, color, texture and protein solubility of

HVEF thawed changed after thawing. Moreover, they verified the thawing of

frozen tuna fish using still air combined with a high voltage electric field.

The results showed increasing the applied voltage and decreasing the electrode

gap significantly elevated specific energy consumption in the combined method,

but decreased it in the electric field method. In addition, electric wind

velocity had a more pronounced effect on the energy consumption [21]. Another

study was done to investigate the effect of high voltage electrostatic field

thawing on the lipid oxidation of frozen tuna fish [22]. The result showed that

lipid oxidation during storage was more intense with increasing voltage as a

result of reducing the electrode gap. However, lipid oxidation decreased by

increasing the electrode gap at a constant voltage. They concluded that the

production and release of the negative ions of air (NIA) and ozone during the

process could lead to the oxidation of the sample surface and to the

degradation of food flavor. Rahbari et al. [18] investigated the parameters

associated with the quality of protein during high-voltage electric field

thawing of frozen chicken breast. Results showed higher myofibrillar protein

solubility and water holding capacity were observed at the starting voltage of

corona and maximized at 2.25 kV/cm electric field strength. Differential

scanning calorimetry thermograms revealed the HVEF-treated samples at 2.25

kV/cm electric field strength showed less protein denaturation than the air-thawed

sample. Nonetheless, by giving rise to the electrical strength up to 3 kV/cm,

protein denaturation increased. Additionally, Jia et al. [23] conducted a study

on high-voltage electrostatic field thawing of frozen rabbit meat and claimed

that this method retained a higher Water Holding Capacity (WHC) and a better

texture quality than still air thawing, and the degree of denaturation for

myofibrillar proteins and some sarcoplasmic proteins was decreased which led to

a better WHC. In another study, a higher abundance of proteins extracted from

-10 kV HVEF thawed pork tenderloin was found compared with the air-thawed

samples. Furthermore, air thawing led to the lowest total sulfhydryl content

and highest carbonyl content compared to the HVEF method [23]. Li et al. [24]

determined the changes in water loss and degradation of adenosine triphosphate

and the microbial community of lightly-salted common carp after HVEF thawing,

and compared this with conventional thawing using still air or running tap

water. They concluded that thawing under 12 kV HVEF at 4 cm electrode distance,

reduced microorganisms significantly (0.5-1 log CFU/g), enhanced adenosine

monophosphate deaminase activity, reduced acid phosphotase activity, and

delayed the degradation of inosine monophosphate compared to the other methods.

In addition, thawing under 12 kV HVEF decreased the water loss of fish cubes (Table 1).

CONCLUSION

The studies reviewed in this article revealed that high voltage

electric field has a great potential for use in the thawing of food. Corrosive

products, especially meat, subjected to HVEF thawing retain higher qualities

than those subjected to conventional methods. In conclusion, by developing

optimum voltages and electrode gaps to create an electric field, the advantages

of this process, as a novel thawing method, will be achieved.

1.

Laohalertdecha S, Naphon P,

Wongwises S (2007) A review of electrohydrodynamic enhancement of heat

transfer. Renewable and Sustainable Energy Reviews 11: 858-876.

2.

Cao W, Nishiyama Y, Koide S

(2004) Electrohydrodynamic drying characteristics of wheat using high voltage

electrostatic field. J Food Eng 62: 209-213.

3.

Taghian Dinani S, Havet M,

Hamdami N, Shahedi M (2014) Drying of mushroom slices using hot air combined

with an electrohydrodynamic (EHD) drying system. Dry Technol 32: 597-605.

4.

Bajgai TR, Hashinaga F,

Isobe S, Raghavan GSV, Ngadi MO (2006) Application of high electric field (HEF)

on the shelf-life extension of embic fruit (Phyllanthus emblica L.).

JFood Eng 74: 308-313.

5.

Hsieh CW, Ko WC (2008)

Effect of high-voltage electrostatic field on quality of carrot juice during

refrigeration. LWT Food Sci Technol 41: 1752-1757.

6.

Singh A, Orsat V, Raghavan

GSV (2012) A comprehensive review on electro hydrodynamic drying and

high-voltage electric field in the context of food and bioprocessing. Drying

Technol 30: 1812-1820.

7.

Havet M, Orlowska M,

Le-Bail A (2009) Effects of an electrostatic field on ice nucleation. In:

Vorobiev E, Lebovka N & Lanoisellé JL [Eds.]. Proceedings of the International

Conference on Bio and Food Electrotechnologies. Compiègne, France: Université

de Technologie de Compiègne.

8.

Xanthakis E, Havet M,

Chevallier S, Abadie J, Le-Bail A (2013) Effect of static electric field on ice

crystal size reduction during freezing of pork meat. Innov Food Sci Emerg

Technol 20: 115-120.

9.

Dalvi M, Hamdami N, Le-Bail

A (2017) Effect of freezing under electrostatic field on selected properties of

an agar gel. Innov Food Sci Emerg Technol 42: 151-156.

10.

Sale AJH, Hamilton WA

(1967) Effects of high electric fields on microorganisms: Killing of bacteria

and yeasts. BBA – General Subjects 148: 781-788.

11.

Hsieh CW, Lai CH, Ho WJ,

Huang SC, Ko WC (2010). Effect of thawing and cold storage on frozen chicken

thigh meat quality by high‐voltage electrostatic field. J Food Sci 75:

M193-M197.

12.

Baumgarten BE (2003) EHD-enhanced

heat transfer in a metallic and a ceramic compact heat exchanger. Department of

Mechanical Engineering, University Maryland.

13.

Li B, Sun DW (2002) Novel

methods for rapid freezing and thawing of foods - A review. J Food Eng 54:

175-182.

14.

James SJ (2002) Meat

refrigeration. 1st Edn. Woodhead Publishing Limited, Abington, pp:

159-163.

15.

Akhtar S, Issa Khan M, Faiz

F (2013) Effect of thawing on frozen meat quality: A comprehensive review. J

Food Sci 23: 198-211.

16.

He X, Liu R, Nirasawa S,

Zheng D, Liu H (2013) Effect of high voltage electrostatic field treatment on

thawing characteristics and post-thawing quality of frozen pork tenderloin meat.

J Food Eng 115: 245-250.

17.

Mousakhani-Ganjeh A,

Hamdami N, Soltanizadeh N (2015) Impact of high voltage electric field thawing

on the quality of frozen tuna fish (Thunnus albacares). J Food Eng 156:

39-44.

18.

Rahbari M, Hamdami N,

Mirzaei H, Jafari SM, Kashaninejad M, et al. (2018) Effects of high voltage

electric field thawing on the characteristics of chicken breast protein. J Food

Eng 216: 98-120.

19.

Bai Y, Sun Y, Li Z, Kang D

(2011) Study the optimum parameters of high voltage electrostatic field

thawing. Proc Eng 16: 679-684.

20.

He X, Liu R, Tatsumi E,

Nirasawa S, Liu H (2014) Factors affecting the thawing characteristics and

energy consumption of frozen pork tenderloin meat using high-voltage

electrostatic field. Innov Food Sci Emerg Technol 22: 110-115.

21.

Mousakhani-Ganjeh A,

Hamdami N, Soltanizadeh N (2016) Thawing of frozen tuna fish (Thunnus

albacares) using still air method combined with a high voltage

electrostatic field. J Food Eng 169: 149-154.

22.

Mousakhani-Ganjeh A,

Hamdami N, Soltanizadeh N (2016) Effect of high voltage electrostatic field

thawing on the lipid oxidation of frozen tuna fish (Thunnus albacares).

Innov Food Sci Emerg Technol 36.

23.

Jia G, Liu H, Nirasawa S,

Liu H (2017) Effects of high-voltage electrostatic field treatment on the

thawing rate and post-thawing quality of frozen rabbit meat. Innov Food Sci

Emerg Technol 41: 348-356.

24.

Li D, Jia Sh, Zhang L, Wang

Zh, Pan J, et al. (2017) Effect of using a high voltage electrostatic field on

microbial communities, degradation of adenosine triphosphate and water loss when

thawing lightly-salted, frozen common carp (Cyprinus carpio). J Food Eng

212: 226-233.

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Agriculture and Forest Meteorology Research (ISSN:2642-0449)

- Journal of Genomic Medicine and Pharmacogenomics (ISSN:2474-4670)

- Advances in Nanomedicine and Nanotechnology Research (ISSN: 2688-5476)

- Journal of Genetics and Cell Biology (ISSN:2639-3360)

- Journal of Veterinary and Marine Sciences (ISSN: 2689-7830)

- Proteomics and Bioinformatics (ISSN:2641-7561)

- Journal of Microbiology and Microbial Infections (ISSN: 2689-7660)