829

Views & Citations10

Likes & Shares

Echinocandin B nucleus an intermediate used in the

production of Anidulafungin a new class of antifungal agent used to treat

chronic fungal infections. Echinocandin B gets converted to Echinocandin B

Nucleus through an enzymatic bioconversion called deacylation by the enzyme

Acylase also called as deacylase. A rapid bioconversion screening method was

performed to select Actinomycete capable of producing Echinocandin B acylase

amongst the group of Actinomycetes strains screened. A total of 140 strains of

Actinomycete isolates were used for the preliminary qualitative plate assay

with 53 strains selected positive for acylase production followed by two

strains selected for quantitative assay. The selected strains were used for

optimizing the bioconversion by varying parameters such as pH, temperature,

feeding time temperature and substrate concentration in lab scale (50 ml

medium) shake flask studies. The effect of temperature on conversion rate was

also optimised. The optimised conditions were also tested in higher volume (500

mL medium) shake flasks which showed a 3 fold increase in conversion rate when

compared to that of lab scale shake flask trials with Actinoplanes utahensis as the control.

Keywords: Antifungals, Echinocandin

B, Anidulafungin, Acylase, Aspergillus

nidulans

INTRODUCTION

The

population of cancer patients, transplant recipients and other individuals

receiving immunosuppressive treatment are at greater risk for fungal infections

because of their weak immune system and the chronic nature of diseases.

Therefore, treatment of such invasive fungal infections has created a major

challenge for health care professionals. Antibiotics are known to target

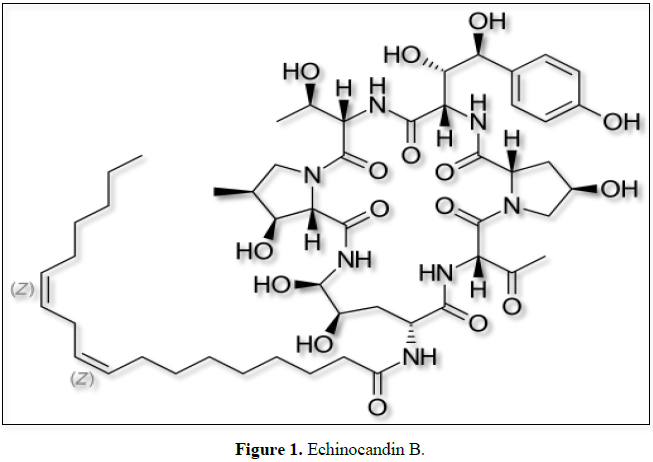

important cellular functions or growth processes of microbes. Echinocandins are

synthetically modified non ribosomal cyclic hexapeptides conjugated with a

fatty acid (Figure 1). They have a

unique mode of action against pathogenic fungi by non-competitively inhibiting

the β-1, 3 D-glucan synthase, a key enzyme involved in the synthesis of β-1, 3

D-glucan, an essential structural component of fungal cell wall [1-4]. They show fungistatic activity

against Aspergillus spp. and

fungicidal activity against several Candida

spp. including strains that are fluconazole resistant. Caspofungin, Micafungin

and Anidulafungin are the three important semisynthetic Echinochandins [5-7].

All have low oral bioavailability and therefore distribute well into tissues

except in CNS and eye. Anidulafungin is a new echinocandin antifungal agent

used extensively for the treatment of oesophageal candidiasis and candidemia.

It is unique in that it undergoes chemical degradation in bile rather than via

hepatic metabolism with longer half-life than Caspofungin or Micafungin.

Anidulafungin is named after the fungus, Aspergillus

nidulans, the first organism reported to produce Echinocandin B (ECB) [8].

Enzymatic deacylation of ECB to a cyclic hexapeptide without a linoleoyl side

chain (Echinocandin B nucleus) and by subsequent chemical reacylation leads to

the formation of anidulafungin [9-12].

Acyl peptides are generally unstable to chemical deacylation and therefore

enzymatic deacylation is widely accepted. Deacylation of Echinochandin B to

Echinochandin B nucleus is catalysed by the acylase (also named as deacylase).

This enzyme is currently identified from Actinoplanes utahensis NRRL

12052. It is a membrane-associated heterodimer composed of 63 kDa and

The present

study was initiated with an aim to identify an organism having a lipopeptide,

acylase, with high specificity towards Echinocandin B. Therefore, a rapid

screening protocol was undertaken with bacteria belonging to Actinomycetes,

isolated from tropical soil. The selected species was evaluated for its

efficiency to bio convert ECB to ECB nucleus and the cultural and environmental

parameters for the bioconversion was optimized.

MATERIALS AND METHODS

Chemicals and reagents

All the

chemicals and reagents used were of analytical grade and were purchased from

Merck. Echinocandin B was prepared in-house by the fermentation of Aspergillus nidulans [13].

Microorganisms and culture conditions

All the

cultures used for screening were isolated from natural sources (Soil, water or

endophytes) across Karnataka, India. The cultures thus isolated were stored as

glycerol stocks at the Biocon India Culture Collection (BICC). Totally, 140

Actinomycetes were cultured on ISP-4 (from Difco medium) plates at 28°C for one

week. The control organism Actinoplanes

utahensis (NRRL 12052) a type strain obtained from Agricultural research

service culture collection (NRRL), Peoria, Illinois.

Enzyme screening studies

Qualitative plate assay for screening of Acylase

producing strains: In the first round of screening, all the 140

Actinomycetes were inoculated onto fresh ISP-4 plates containing 1 mg/ml of

Echinocandin B. The plates were incubated at 30°C for 7 days and at the end of

the incubation, the plates were overlaid with 5 mL of soft agar containing 103

CFU/mL of Candida albicans.

[14]. The overlaid plates were further incubated at 30°C for 24 h and the

plates with the growth of C. albicans

were considered as positive for acylase.

Quantitative assay for

production of acylase under submerged fermentation (SMF): Fifty-three strains positive for acylase were selected from

quantitative plate assay. These strains were further inoculated into

Streptomyces seed media (4% glucose, 1% yeast extract, 0.1% CaCO3,

pH adjusted to 6.5 and 25 mL of the media was dispensed into 250 mL flask) and

incubated at 28°C for 3 days in an orbital shaker at 230 rpm. Three mL of the

inoculum was transferred into production medium (4% glucose, 1% Soya peptone,

1% yeast extract, 1% KH2PO4, 0.5% K2HPO4,

0.1% KCL, 0.01% calcium carbonate, pH adjusted to 7.0 and 30 mL of the media

was dispensed into 250 mL flask) containing filter sterilized Echinocandin B

(dissolved in methanol) at a concentration of 3.0 g/L and incubated at 30°C for

3 days in an orbital shaker at 230 rpm. Samples were withdrawn at an interval

of 24 h from the time of inoculation, centrifuged at 3000 rpm for 15 min and

the supernatant was analysed for the formation of Echinocandin B nucleus by

HPLC. Agilent Poroshell EC18 (150*4.6 mm, 2.7 µm pore size) column with KH2PO4

buffer and HPLC grade Acetonitrile mobile phases used for HPLC analysis using

Echinocandin B and Echinocandin B nucleus from standard commercial sources

[15].

The

production of Acylase in Streptomyces seed and production media (devoid of the

substrate – Echinocandin B) were analysed by separating the cells by

centrifugation at 3000 rpm for 15 min. 1 g/L of Echinocandin B (in 50 mM

phosphate buffer at pH 7) was added to the cell free supernatant and incubated

for 24 h at 30°C. The reaction mixture was centrifuged at 3000 rpm for 15 min

and the supernatant was analysed in HPLC (as described above) to detect

Echinocandin B nucleus.

Optimisation studies for bioconversion of Echinocandin B

to Echinocandin B nucleus

For the

optimisation studies different parameters which affect the bioconversion of

Echinocandin B to Echinocandin B nucleus were studied which include pH,

temperature, substrate concentration, feeding time and media volume. Two

strains positive for acylase production coded as BICC-8848, BICC-8547 with a

control organism Actinoplanes utahensis

in the production media were studied under submerged fermentation conditions.

These strains were inoculated into Streptomyces seed media and incubated at

28°C for 3 days in an orbital shaker at 230 rpm. Three mL of the

inoculum was transferred into production medium and incubated at 30°C for 3

days in an orbital shaker at 230 rpm. Samples (1 mL) were withdrawn at an

interval of 24 h from the time of inoculation till end of incubation,

centrifuged at 3000 rpm for 15 min and the supernatant was analysed for the

formation of Echinocandin B nucleus by HPLC (as described in section 2.2.2)

[15].

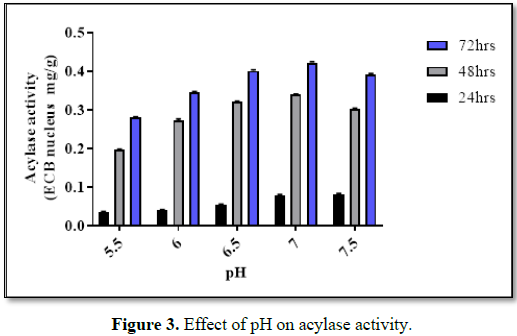

Effect of pH

The

production medium was adjusted to pH ranges (5.5, 6.0, 6.5, 7.0 and 7.5) with

10% H3PO4/10% NaOH before sterilization. The sterile

medium was supplemented with the substrate Echinocandin B (3 g/L) before they

were inoculated with the cultures.

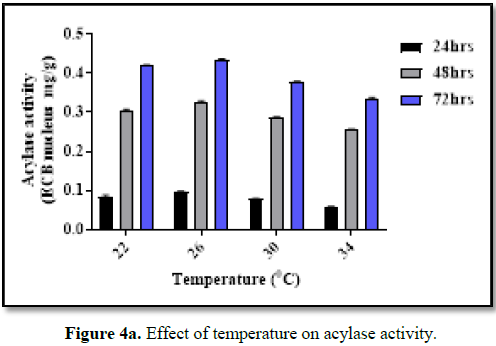

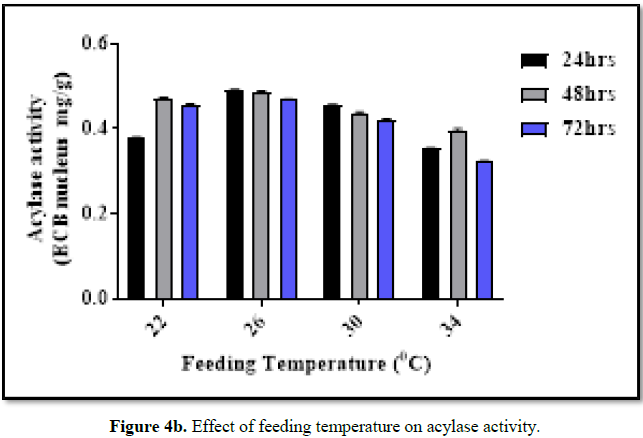

Effect of temperature

The

inoculated production medium was incubated at different temperature (22°C, 26°C,

30°C and 34°C) for 72 h in an orbital shaker at 230 rpm. Samples were withdrawn

at regular interval of time (every 24 h) and analysed by HPLC.

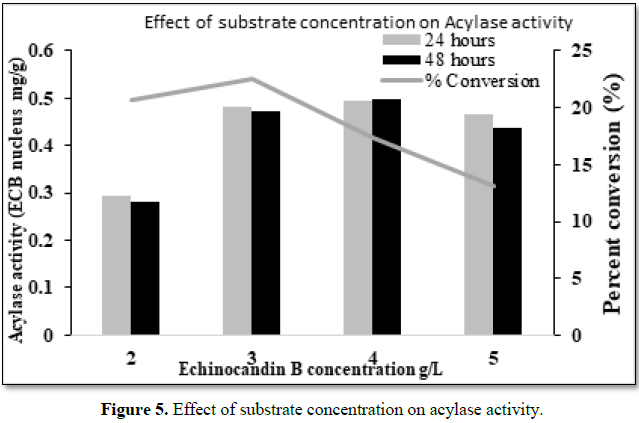

Effect of substrate concentration

The

inoculated production medium was fed with Echinocandin B at different

concentrations (2, 3, 4, 5 g/L) incubated at 26°C for 72 h in an orbital shaker

at 230 rpm. Samples were withdrawn at regular interval of time (every 24 h) and

analysed by HPLC.

Effect of feeding time of substrate

The

inoculated production medium was incubated at 26°C in an orbital shaker at 230

rpm and fed with Echinocandin B (3 g/L) at regular intervals from the time of

inoculation (0, 24, 48, 72, 96, 120 h). Samples were withdrawn at regular

interval of time (every 24 h) and analysed by HPLC.

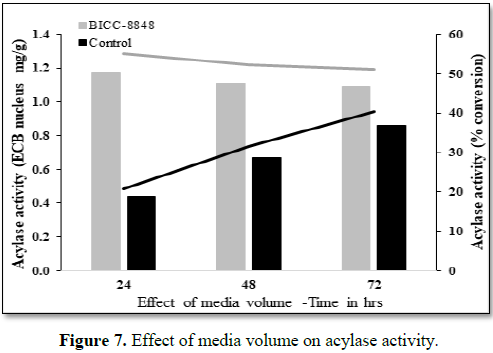

Effect of media volume on bioconversion

In general,

the acylase activity varies depending on the volume of the medium used in the

shake flasks. The pre-grown culture in the seed medium was inoculated into

production media (500 mL in 2000 mL conical flask adjusted to pH 7.0) and

incubated at 30

Molecular level Identification of the

selected Actinomycete

Two strains

(BICC-8848 and BICC-8547) were identified to produce the enzyme. Genomic DNA

from the selected Actinomycetes was extracted; 16S rRNA gene was amplified

using 16 S universal primers. The amplified PCR product was sequenced, the

obtained sequence was checked in NCBI BLAST analyser and identification is made

based on the maximum homology to the available sequence in the NCBI database

[16].

RESULTS

Qualitative plate assay for screening for Echinocandin B

acylase producing strains

A total of

140 isolates belonging to Actinomycetes were screened by plate assay method and

53 isolates (37%) were found to be positive for converting the Echinocandin B,

an antifungal compound, into a non-effective molecule, Echinocandin B Nucleus.

Growth of Candida albicans around the

Actinomycete colony in the soft agar was an indication of bioconversion.

Satoshi et al. [14] screened 3300 Actinomycetes and 500 fungal strains and were

able to select 22 Actinomycetes (0.6% only) and 2 fungal strains (0.06% only)

positive for the bioconversion.

Quantitative assay for production of acylase under

submerged fermentation (SMF)

Actinomycetes

isolates (53 in number) selected from the plate assay method of screening were

subjected to second round of screening by submerged fermentation, for the

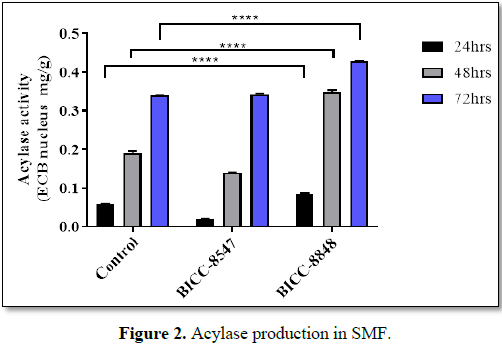

selection of strains with higher Acylase activity. Two Streptomyces species

were selected, coded as BICC 8547 and BICC 8848. Among the two, BICC 8547

showed acylase activity equivalent to that of the control micro-organism (Figure 2). However, BICC 8848 showed

higher activity (25 to 30% more) of Acylase compared to the control organism

and therefore selected for further studies. The cell free supernatant fed with

1 g/L Echinocandin B showed very poor conversion.

The acylase

activity is directly proportional to the conversion of ECB to ECB nucleus. Therefore,

the activity of the acylase was determined by the titre value of ECB nucleus

which was quantified by HPLC analysis

Effect of pH and temperature

The optimal

pH and temperature for acylase activity (for bioconversion) of BICC-8848 was

found to be optimal at pH of 7.0 and at temperature of 26

Effect of substrate concentration

Any

substrate beyond a particular concentration can be toxic to cells or can reduce

the activity of the enzyme. Echinocandin B was fed at different concentrations

to production broth and we could observe higher conversion rate at 4 g/L, but,

however, the conversion rate was decreased when the concentration of the

substrate was increased (Figure 5).

Effect of feeding time of substrate on conversion rate

In the

process of determining the optimal pH and temperature for bioconversion, it was

observed that the impurity level was higher than the control. Therefore, an

attempt was made to decrease the level of impurity by adding the substrate at

different duration of growth of the culture in production media. Interestingly,

it was observed that BICC-8848 was able to convert the substrate in 24 h by

lowering the impurity. However, it was also observed that the concentration of

the product decreased from 48 h onwards with increased impurity (Figure 6).

Effect of media volume on bioconversion

An attempt

was made to evaluate the efficiency of the conversion with respect to volume of

the media taken. The percentage conversion was observed to be generally lower

in lower volume of broth, therefore trial was performed in higher volume, i.e.,

500 mL of media (in 2 L conical flask) with the above set parameters and was

observed that the conversion rate was as high as 55.0% when compared to 22.5%

in 100 mL medium after 24 h of incubation. The conversion in BICC-8848 was

completed in 24 h while the conversion in control strain proceeded till 72 h

and the maximum conversion was 40.2% at the end of 72 h (Figure 7). It is evident that maximum conversion is achieved with

higher volume with respect to mass balance ratio.

Molecular level identification of culture

The

actinomycetes strain BICC-8848 when subjected to ribotyping match only 99% with

other Streptomyces species, showing only 98% homology to Streptomyces spp. B180, Streptomyces

parvus and Streptomyces sindenensis.

These Streptomyces spp. have not been

reported so far to possess the acylase activity and the strain Streptomyces sp. BICC-8848 is a strain

with better Acylase activity (better than Actinoplanes

utahensis NRRL 12052) which can be studied further with detailed taxonomic

studies such as genome sequencing and comparative studies to identify it till

species level.

GenBank

accession number SUB4743646 SEQ1 MK123323

DISCUSSION AND

CONCLUSION

Deacylation

is a critical step in the semi-synthetic production of various novel

lipopeptides. The enzymatic deacylation of Echinocandin B to Echinocandin B

nucleus is an important step followed by chemical reacylation with an optimized

acyl group to get a pharmacologically important antifungal drug, Anidulafungin

[17]. These steps are conveniently and efficiently carried out by microbes when

incubated with suitable substrate. The present investigation was taken up in

search of an Actinomycete with better acylase activity. The preliminary data

obtained in our present study revealed that the selected Actinomycete (Streptomyces spp. BICC-8848) possess acylase with good conversion rate (up to 55%

conversion rate compared to 22% in control organism) at standard growth

conditions than few Streptomyces and fungal organisms reported earlier. The molecular characteristics of our isolate of

Streptomyces show only 99% similarity to any of the species within the genus described

to date [18-20]. This species of Streptomyces could be a novel one, an

additional Actinomycete member, under the family of acylase producers.

Structural elucidation of acylase protein of this novel Streptomyces species

would be studied further, to understand its structure-function relationship [21].

ACKNOWLEDGMENT

The authors thank department of Microbiology and Biotechnology, Bangalore

University and Biocon Ltd.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

1. Wiederhold

NP, Lewis RE (2003) The echinocandin antifungals: An overview of the

pharmacology, spectrum and clinical efficacy. Expert Opin Investig Drugs 12:

1313-1333.

2. Denning

DW (2003) Echinocandin antifungal drugs. Lancet 362: 1142-1151.

3. Odds

FC, Brown AJ, Gow NA (2003) Antifungal agents: Mechanisms of action. Trends

Microbiol 11: 272-279.

4. Zaas

AK, Alexander BD (2005) Echinocandins: Role in antifungal therapy. Expert Opin

Pharmacother 6: 1657-1668.

5. Sucher

AJ, Chahine EB, Balcer HE (2009) Echinocandins: The newest class of

antifungals. Ann Pharmacother 43: 1647-1657.

6. Wagner

C, Graninger W, Presterl E, Joukhadar C (2006) The echinocandins: Comparison of

their pharmacokinetics, pharmacodynamics and clinical applications.

Pharmacology 78: 161-177.

7. Cleary

JD (2009) Echinocandins: Pharmacokinetic and therapeutic issues. Curr Med Res

Opin 25: 1741-1750.

8. Nyfeler

R, Keller-Schierlein W (1974) Metabolites of microorganisms 143 Echinocandin B,

a novel polypeptide-antibiotic from Aspergillus

nidulans var. echinulatus:

Isolation and structural components. Helv Chim Acta 57: 2459-2477.

9. Debono

M, Abbott BJ, Turner JR, Howard LC, Gordee RS, et al. (1988) Synthesis and

evaluation of LY121019, a member of a series of semisynthetic analogues of the

antifungal lipopeptide echinocandin Ba. Ann N Y Acad Sci 544: 152-167.

10. Onishi

J, Meinz M, Thompson J, Curotto J, Dreikorn S, et al. (2000) Discovery of novel

antifungal (1,3)-D-glucan synthase inhibitors. Antimicrob Agents Chemother 44:

368-377.

11. Petraitiene

R, Petraitis V, Groll AH, Candelario M, Sein T, et al. (1999) Antifungal

activity of LY303366, a novel echinocandin B, in experimental disseminated

candidiasis in rabbits. Antimicrob Agents Chemother 43: 2148-2155.

12. Uzun

O, Kocagöz S, Cetinkaya Y, Arikan S, Unal S (1997) In vitro activity of a new echinocandin, LY303366, compared with

those of amphotericin B and fluconazole against clinical yeast isolates.

Antimicrob Agents Chemother 41: 1156-1157.

13. Abbott

BJ, Fukuda DS; Eli Lilly and Company (1982) United States Patent 4322338.

14. Satoshi

U, Kazunori S, Nobutaka O, Masaru T, Michio Y, et al. (2010) Screening and

characterization of microorganisms with FR901379 acylase activity. J

Antibiotics 63: 65-70.

15. Ueda

S, Shibata T, Ito K, Oohata N, Yamashita M, et al. (2011) Cloning and

expression of the FR901379 acylase gene from Streptomyces sp. no. 6907. J Antibiotics 64: 169-175.

16. Rintala

H, Nvalainen A, Ronka E, Suutari M (2001) PCR primer targeting the 16s RNA gene

for the specific detection of Streptomyces. Mol Cell Probes 15: 337-347.

17. Barrett

D (2002) From natural products to clinically useful antifungals. Biochem

Biophys Acta 1587: 224-233.

18. Kauffman

CA, Carver PL (2008) Update on echinocandin antifungals. Semin Respir Crit Care

Med 29: 211-219.

19. Monk

BC, Goffeau A (2008) Outwitting multidrug resistance to antifungals Science

321: 367-369.

20. Paolo

B, Diana DG, Fabio F, Maurizio R (2007) Vanillin production using metabolically

engineered Escherichia coli under

non-growing conditions. Microbial Cell Factories 6: 13.

21. Wenwen

C, Erzheng S, Shujing Z, Yuhong R, Dongzhi W (2014) Characterization of a

nitrilase from Arthrobacter aurescens

CYC705 for synthesis of iminodiacetic acid. J Gen Appl Microbiol 60: 207-214.